E-SMARTFORKS

-30/+40 °C (-22/104°F)

warehouse temperature range

24/7

Performance monitoring

0

data collection points

Welcome

To the future

Welcome

To the future

Welcome

To the future

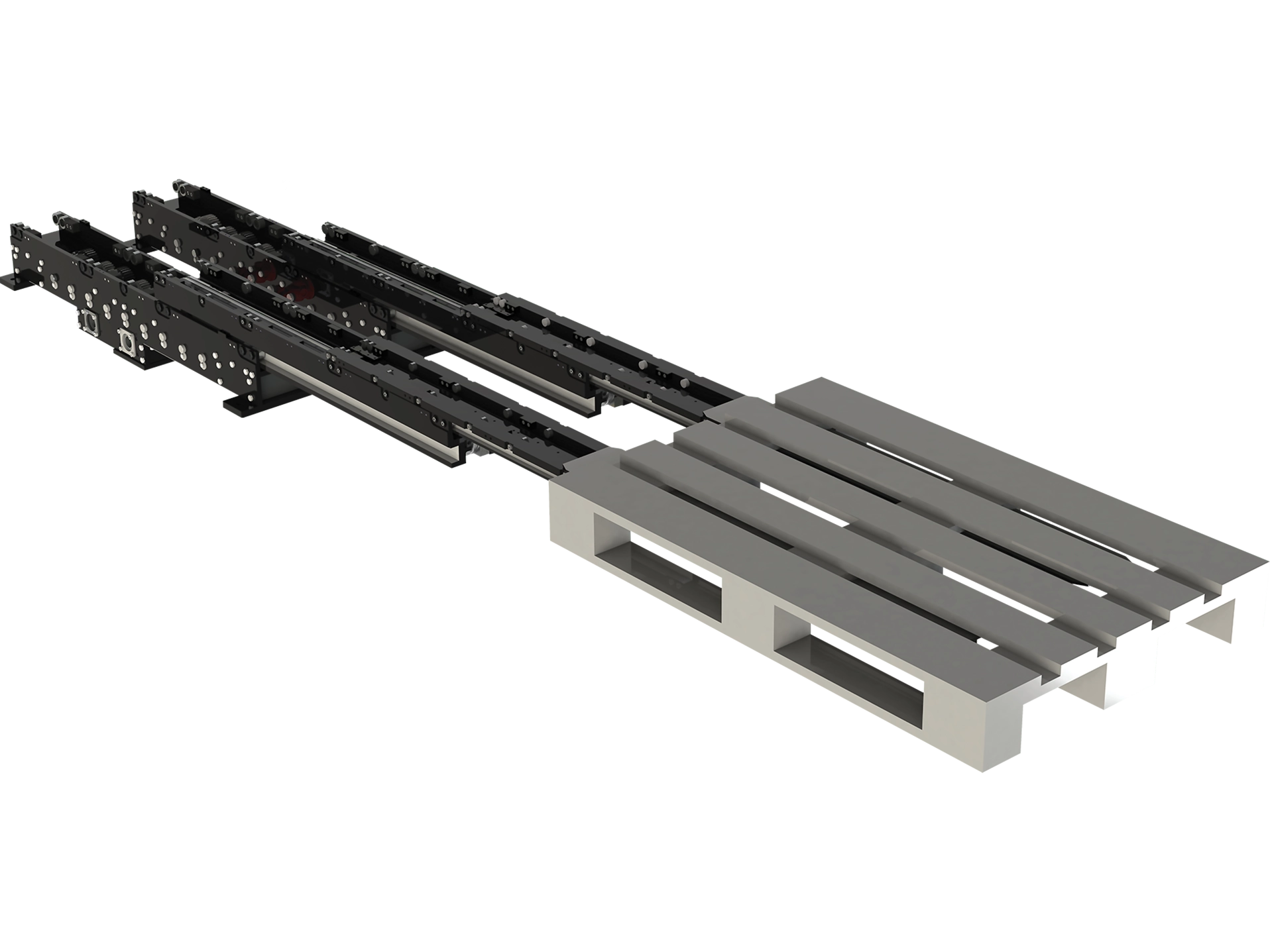

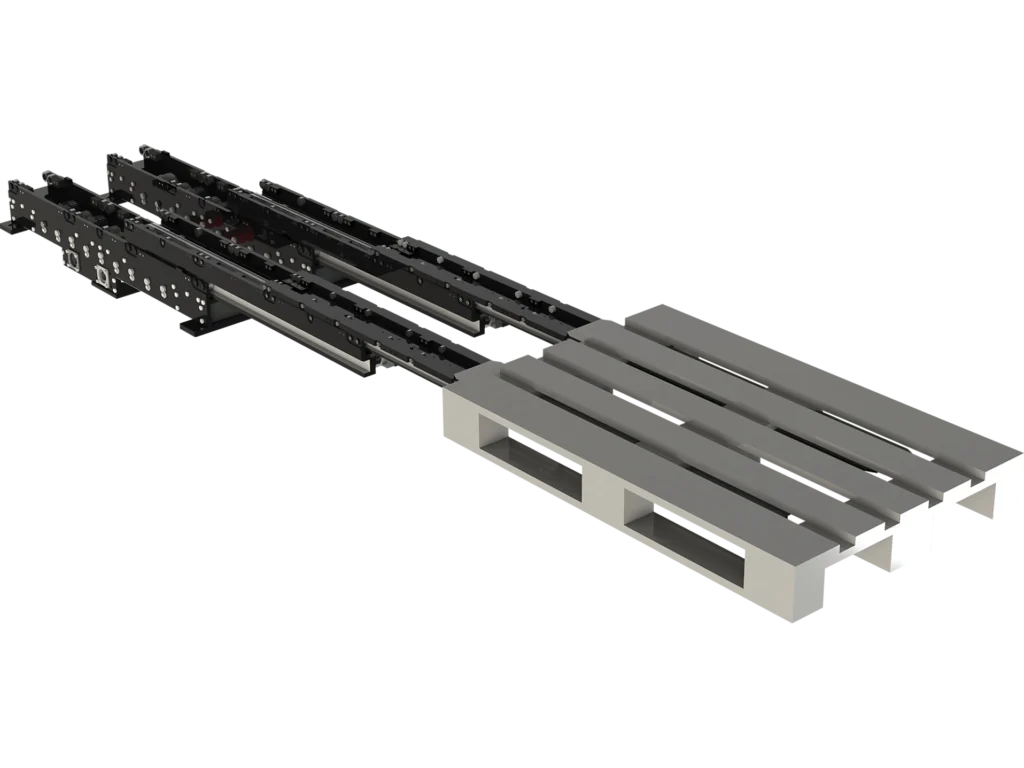

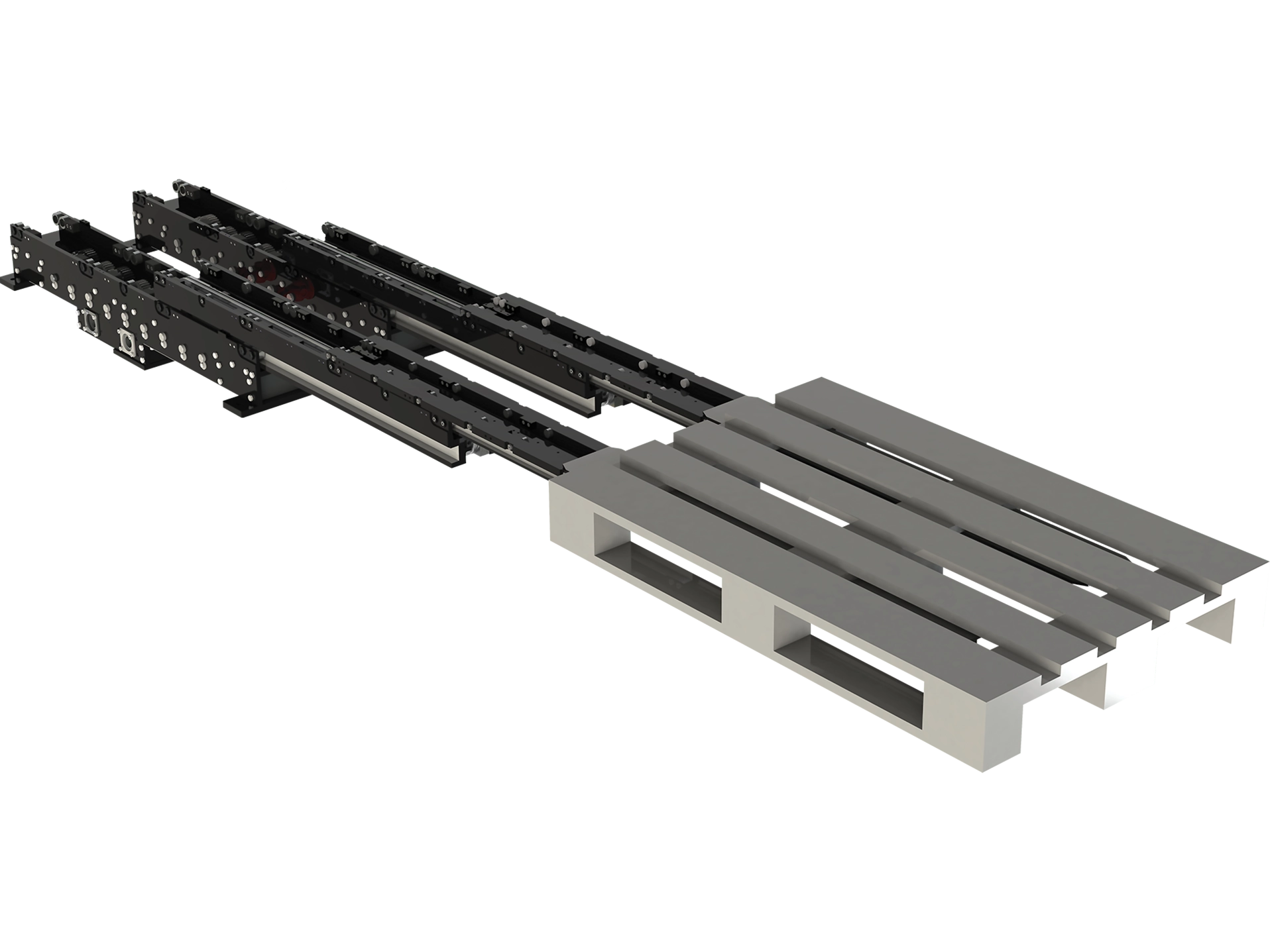

E-Smartforks: The evolution of telescopic forks

E-Smartforks: The evolution of telescopic forks

PREDICTIVE MAINTENANCE

For any company, it is essential to maintain high and tracked storage performance within its automated ASRS warehouse. To ensure suitable working conditions, prevent pallet handling disruptions due to unexpected events or unforeseen increases in operating costs, Eurofork has created the new frontier of telescopic forks

5.0 EVOLUTION

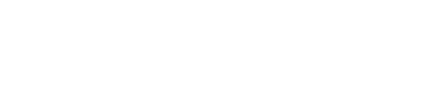

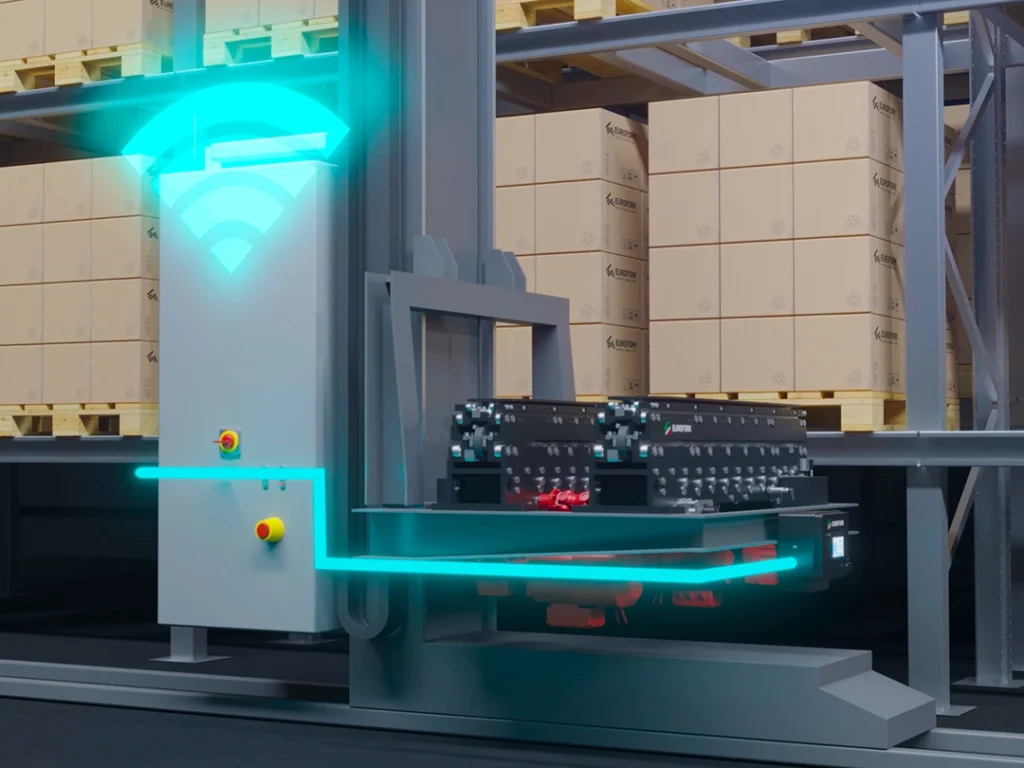

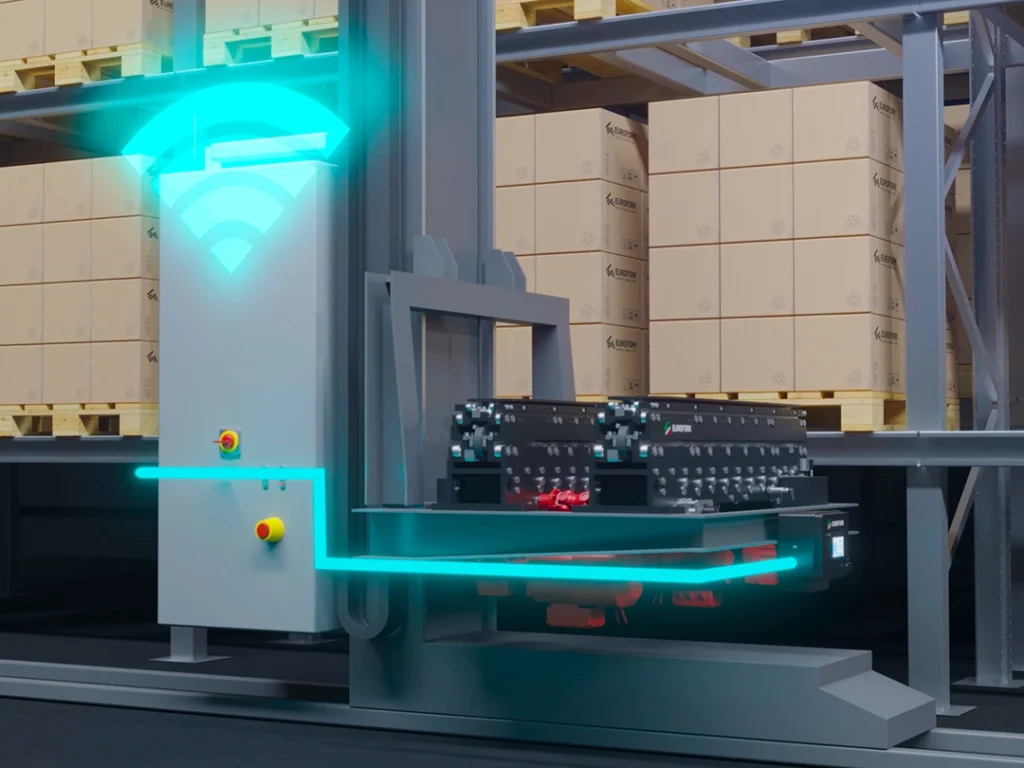

We have leveraged our expertise in automated handling and technology development of pallet shuttles to create E-SMARTFORKS, the technological evolution of telescopic forks. E-SMARTFORKS represent the ultimate solution to eliminate uncertainty and keep your warehouse always operational. Equipped with advanced sensors and IoT devices from leading brands, they can monitor the status of the handling device in real time, anticipating any issues and supporting predictive maintenance, without the need for interconnection with the company’s MES and ERP systems.

E-SMARTFORKS

Mitigating the risk of downtime is at the core of our solution, thanks to the continuous analysis of operational condition data. E-SMARTFORKS utilize advanced technology to analyze operational data in real time, enabling proactive measures to reduce the risk of downtime. This innovative approach ensures that potential issues are identified and resolved before they can impact productivity.

E-SMARTFORKS emphasizes predictive maintenance, transforming the concept of optimizing maintenance time and frequency through advanced big data collection capabilities. This process allows for the adaptation and scheduling of maintenance activities based on the specific needs of the device. By leveraging data analysis, E-SMARTFORKS minimize downtime and enhance operational efficiency.

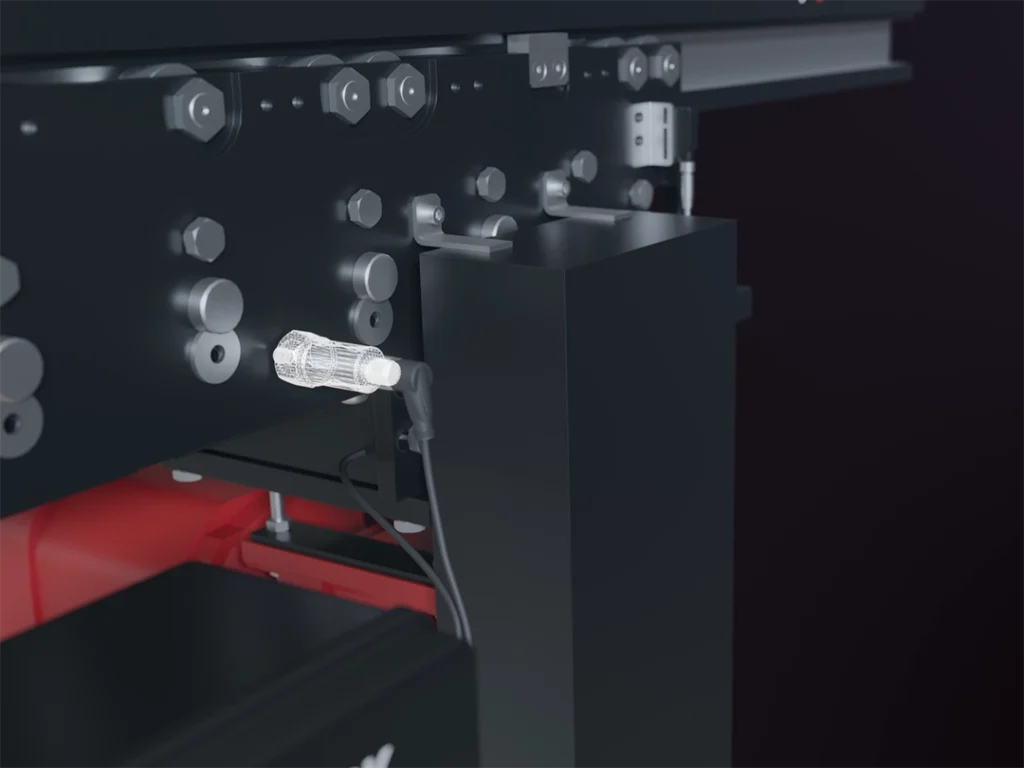

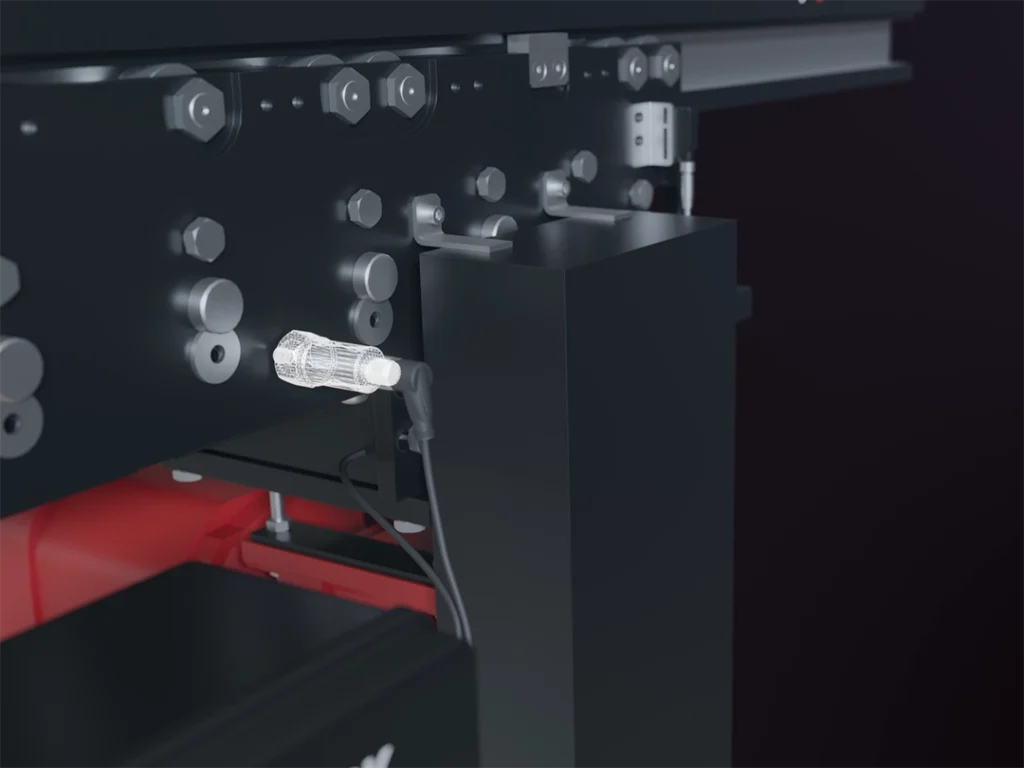

E-SMARTFORKS represent a new benchmark for the performance of handling devices. Thanks to the integration of dedicated sensors and IoT devices, it is possible to safeguard the accuracy and control of the device’s performance, maintaining high standards in both torque management and precision control.

Equipped with dedicated sensors for continuous temperature monitoring, E-SMARTFORKS ensures 24/7 protection of component longevity. Meticulously designed to withstand extreme environmental challenges, each fork offers reliable and durable performance. The integrated temperature monitoring system allows for timely detection of variations and enables preventive interventions.

E-SMARTFORKS introduce a revolutionary feature with automatic alert notifications, enhancing capabilities in cloud solutions for big data. Once the controller is installed, the system takes care of monitoring and automatically sends email notifications for any triggered alerts. This innovative functionality allows the system to proactively manage the forks, thereby improving operational efficiency.

E-SMARTFORKS, through their advanced data collection capabilities, enable continuous machine learning, marking a significant advancement in automated handling technology. Thanks to cutting-edge machine learning algorithms, E-SMARTFORKS gather valuable real-time operational insights, allowing for a detailed understanding of their environment.

Mitigating the risk of downtime is at the core of our solution, thanks to the continuous analysis of operational condition data. E-SMARTFORKS utilize advanced technology to analyze operational data in real time, enabling proactive measures to reduce the risk of downtime. This innovative approach ensures that potential issues are identified and resolved before they can impact productivity.

E-SMARTFORKS emphasizes predictive maintenance, transforming the concept of optimizing maintenance time and frequency through advanced big data collection capabilities. This process allows for the adaptation and scheduling of maintenance activities based on the specific needs of the device. By leveraging data analysis, E-SMARTFORKS minimize downtime and enhance operational efficiency.

E-SMARTFORKS represent a new benchmark for the performance of handling devices. Thanks to the integration of dedicated sensors and IoT devices, it is possible to safeguard the accuracy and control of the device’s performance, maintaining high standards in both torque management and precision control.

Equipped with dedicated sensors for continuous temperature monitoring, E-SMARTFORKS ensures 24/7 protection of component longevity. Meticulously designed to withstand extreme environmental challenges, each fork offers reliable and durable performance. The integrated temperature monitoring system allows for timely detection of variations and enables preventive interventions.

E-SMARTFORKS introduce a revolutionary feature with automatic alert notifications, enhancing capabilities in cloud solutions for big data. Once the controller is installed, the system takes care of monitoring and automatically sends email notifications for any triggered alerts. This innovative functionality allows the system to proactively manage the forks, thereby improving operational efficiency.

E-SMARTFORKS, through their advanced data collection capabilities, enable continuous machine learning, marking a significant advancement in automated handling technology. Thanks to cutting-edge machine learning algorithms, E-SMARTFORKS gather valuable real-time operational insights, allowing for a detailed understanding of their environment.

SUBSCRIBE AND

DISCOVER MORE

Fill in the form to download the brochure

Discover our

Success stories

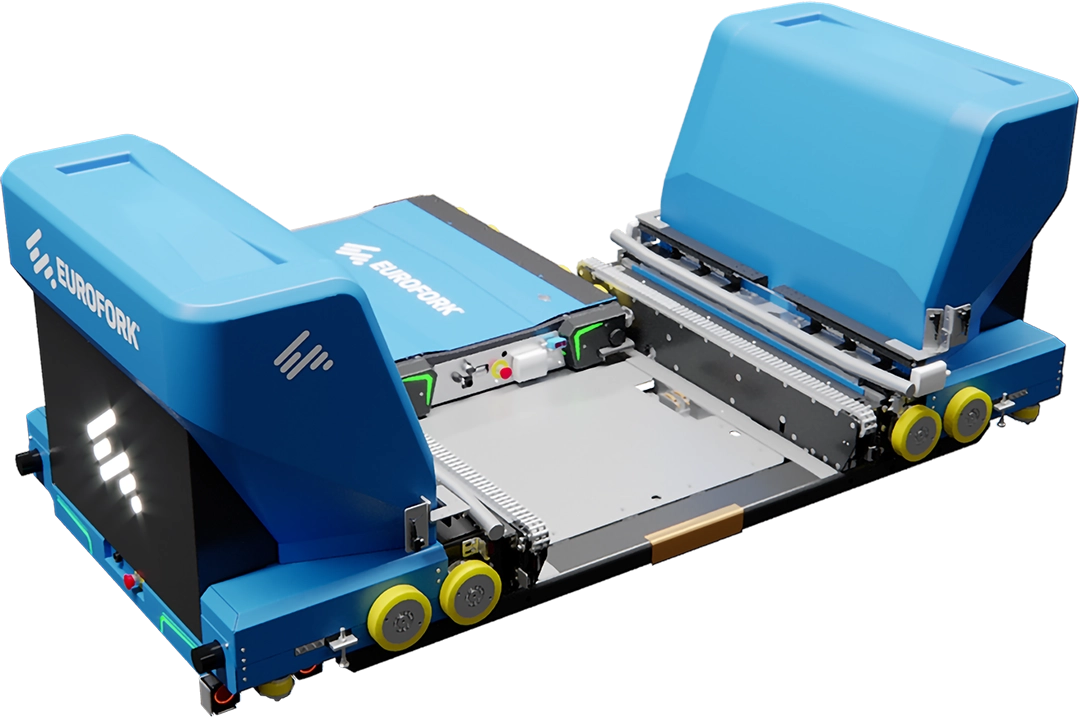

With over 130,000 applications installed in more than 93 countries, our automatic handling systems are considered among the most reliable in the intralogistics automation landscape.

Our complete solution portfolio responds to any automatic handling need, allowing us to be the ideal partner for System Integrators and offering support as a solution provider for any project.

Discover our success stories!

Contact Us

To request further information, fill out the form. Our sales department is available to help you with your next intralogistics automation project.

Related SOLUTIONS

Telescopic forks

With more than 130,000 units installed across over 93 countries, our telescopic forks are widely recognized as some of the most dependable solutions in the field of intralogistics automation.

Related SOLUTIONS

Telescopic forks

With more than 130,000 units installed across over 93 countries, our telescopic forks are widely recognized as some of the most dependable solutions in the field of intralogistics automation.

Related SOLUTIONS

Telescopic forks

With more than 130,000 units installed across over 93 countries, our telescopic forks are widely recognized as some of the most dependable solutions in the field of intralogistics automation.

Eurofork

solutions

Portfolio

Reliability, innovation, and high performance: these are the qualities that make our automated handling systems the ideal choice for improving the efficiency of your warehouse or production line.

With a comprehensive range of solutions designed for every need, we offer cutting-edge technologies to maximize productivity and optimize space.

Discover the complete portfolio