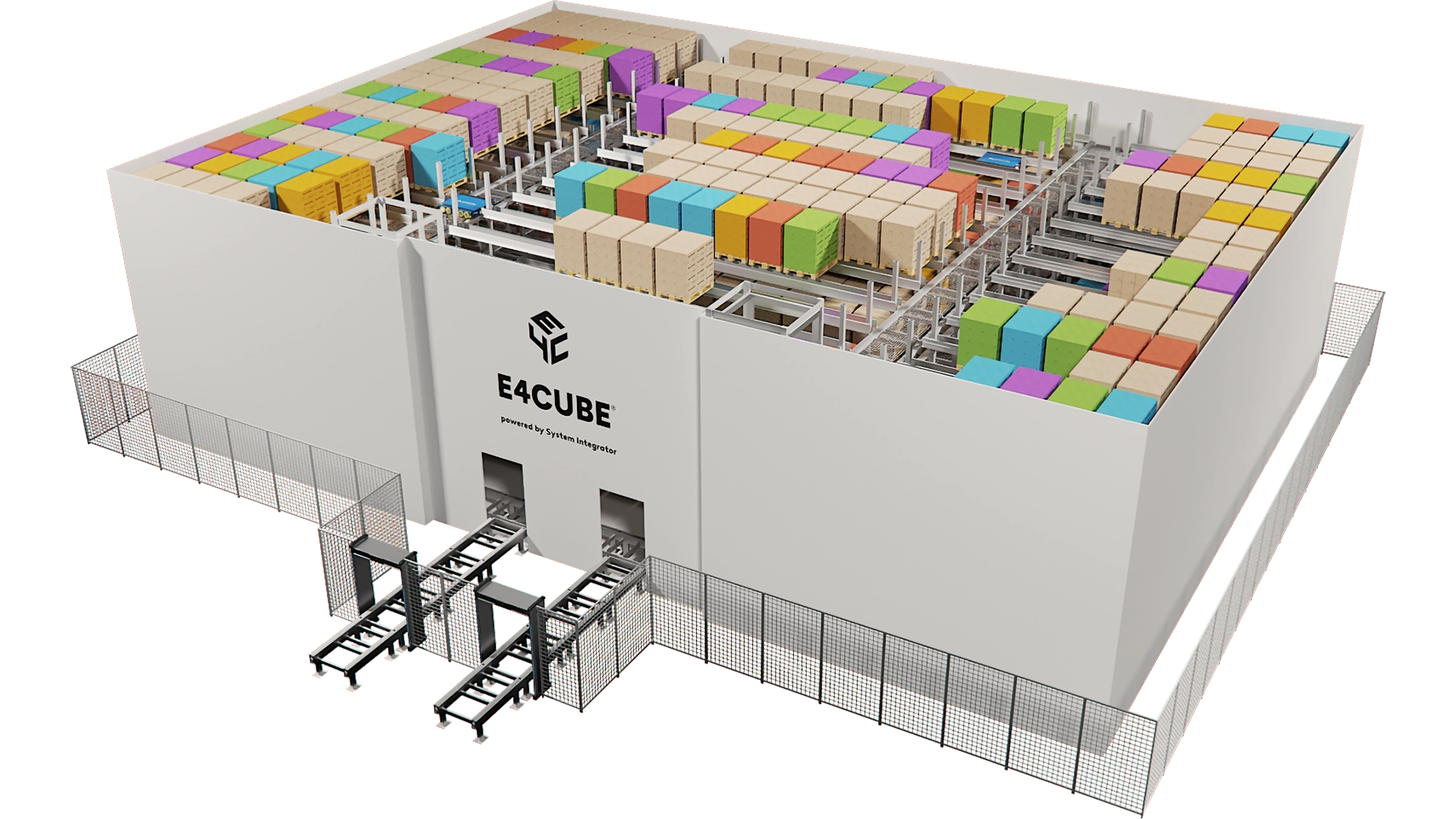

E4CUBE®: the plug-and-play automated storage system

0

months for go live

0

%of savings on the TCO

0

%Of space saved

Warehouse

ready

to fill

Warehouse

ready

to fill

Warehouse

Ready

To fill

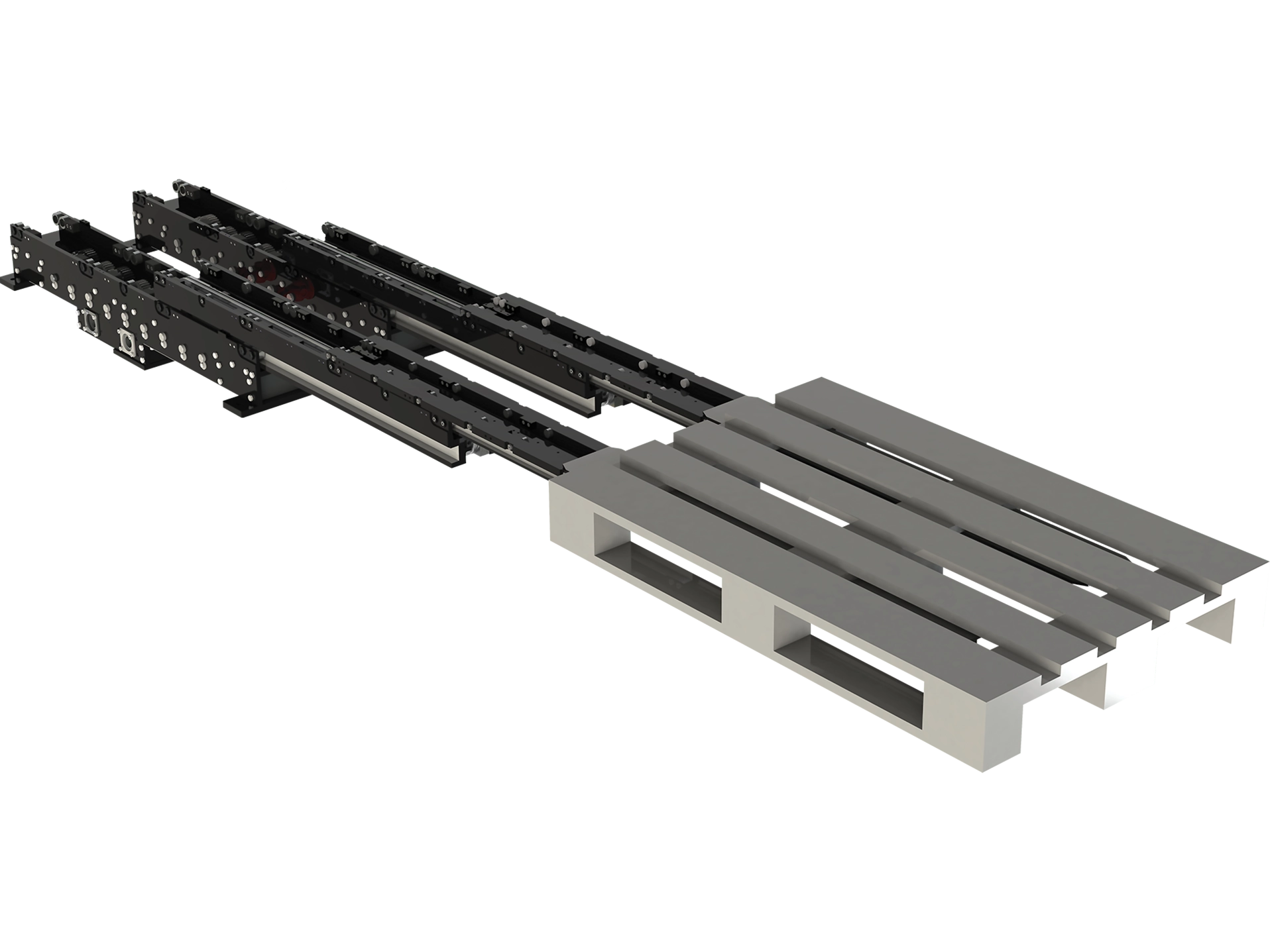

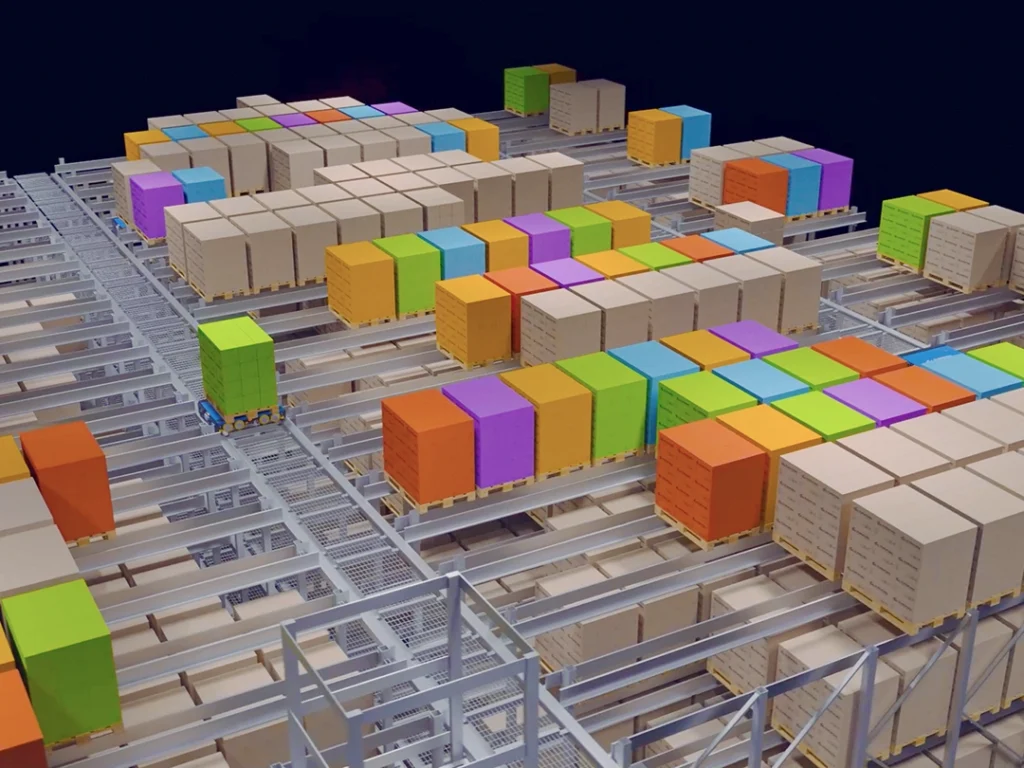

A modular pallet handling system for automated warehouses

A modular pallet handling system for automated warehouses

DESIGNED FOR SYSTEM INTEGRATORS READY FOR THE END USER

Companies often rely on system integrators for solutions related to pallet handling that are standard, flexible, future-proof, and sustainable. We have designed E4CUBE® by Eurofork for our system integrator partners, revolutionizing the concept of automatic pallet storage—standard yet incredibly flexible.

STANDARD BUT FLEXIBLE

E4CUBE® by Eurofork is a highly versatile and innovative plug-and-play warehouse that offers a wide range of standard and modular configurations to fully meet the needs of system integrators. Its unparalleled flexibility and rapid implementation allow E4CUBE® to easily adapt to existing spaces and be operational in just 6 months, from order to Go Live.

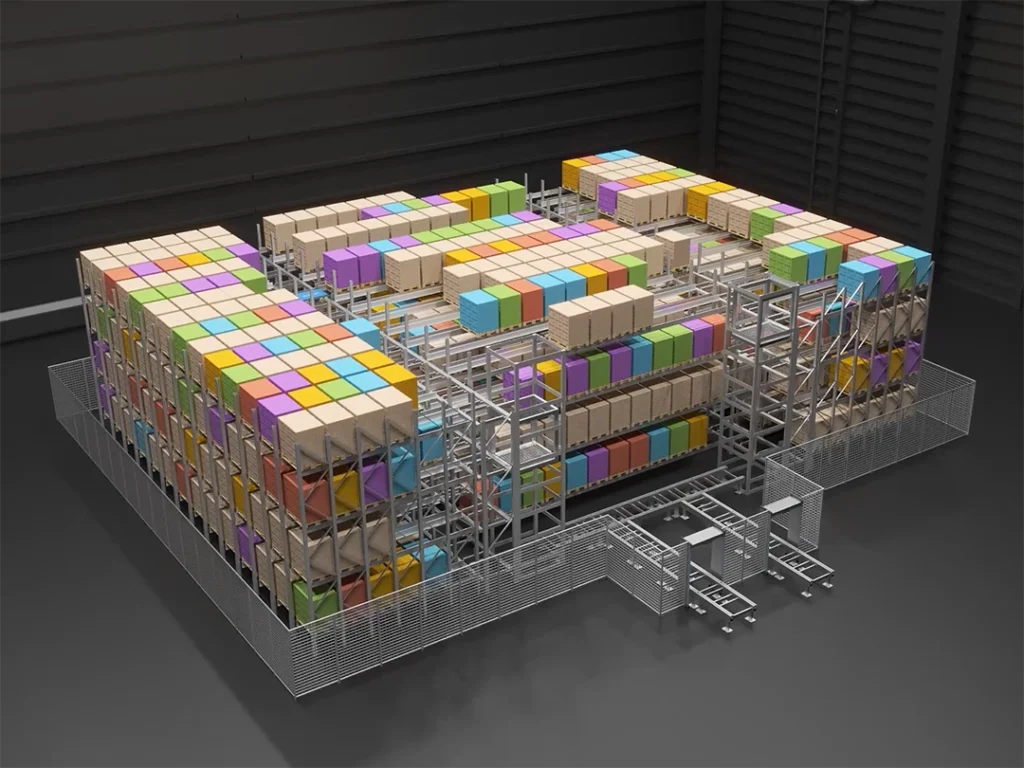

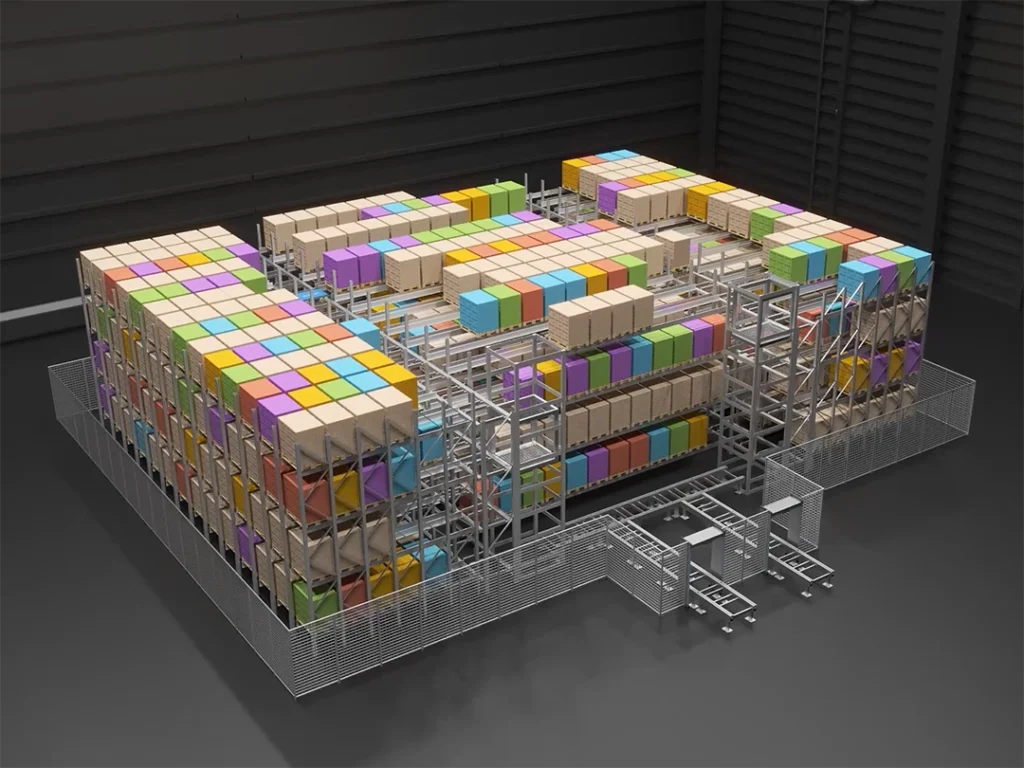

VOLUMETRIC EFFICIENCY AND DESIGN

E4CUBE® offers an unparalleled solution in terms of storage density, maximizing available space. Thanks to its innovative design, it optimizes every millimeter, allowing for efficient resource management. Designed to meet advanced storage needs, E4CUBE® stands out for its ability to adapt to different contexts, making it an ideal choice for those seeking high performance as well as versatility.

E4CUBE

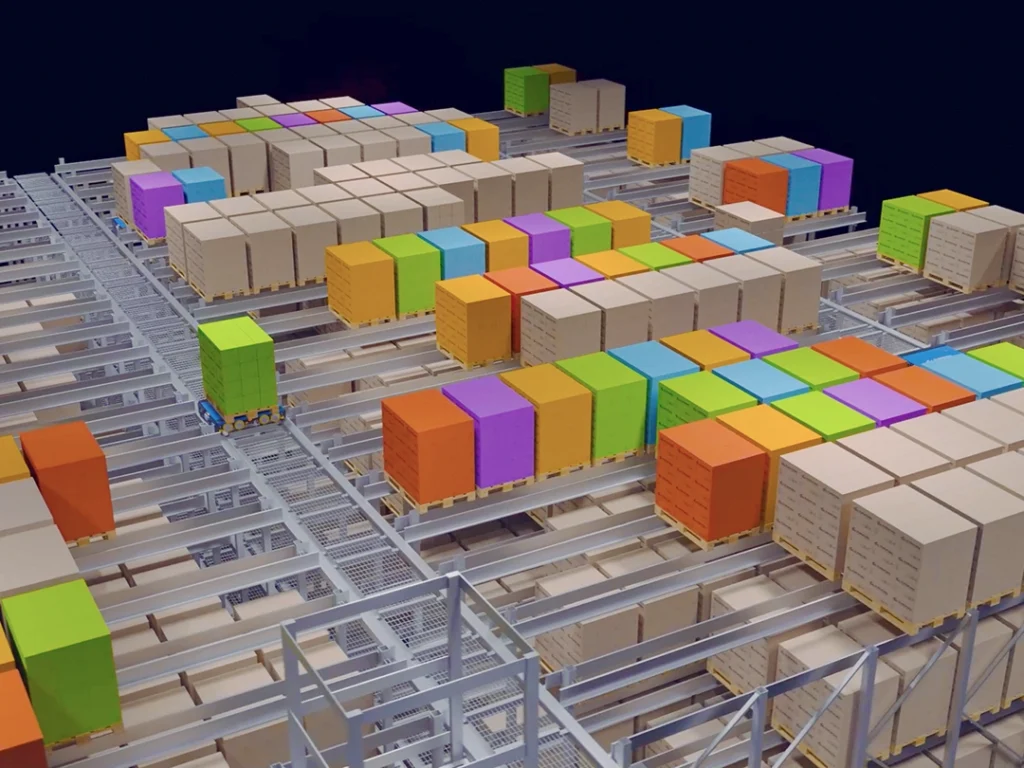

Forget the limits of traditional automatic warehouses. The incredible turnover rate of E4CUBE®, ranging from 17 to 737, allows for the entire warehouse to be emptied or filled over 700 times in a working year. This operational flexibility translates into dynamic resource management, optimizing turnover rates and maximizing productivity.

E4CUBE® guarantees savings of up to 55% on the total cost of ownership (TCO), ensuring highly efficient financial management. E4CUBE® is also available for lease (operational or financial) with no upfront payment, allowing for immediate access and an excellent return on investment. This arrangement significantly reduces expenses compared to traditional solutions, improving long-term operating costs and offering excellent ROIC.

E4CUBE®, thanks to the reduced volume and weight of the E4SHUTTLE pallet shuttles that handle the load units, offers exceptional energy efficiency, reducing consumption by up to 80% compared to traditional solutions. Furthermore, this solution emits less CO2 than other warehouse automation systems. The CO2 emissions of E4CUBE® are offset by purchasing Carbon Credits from UN-certified entities, making it the greenest automation solution on the market.

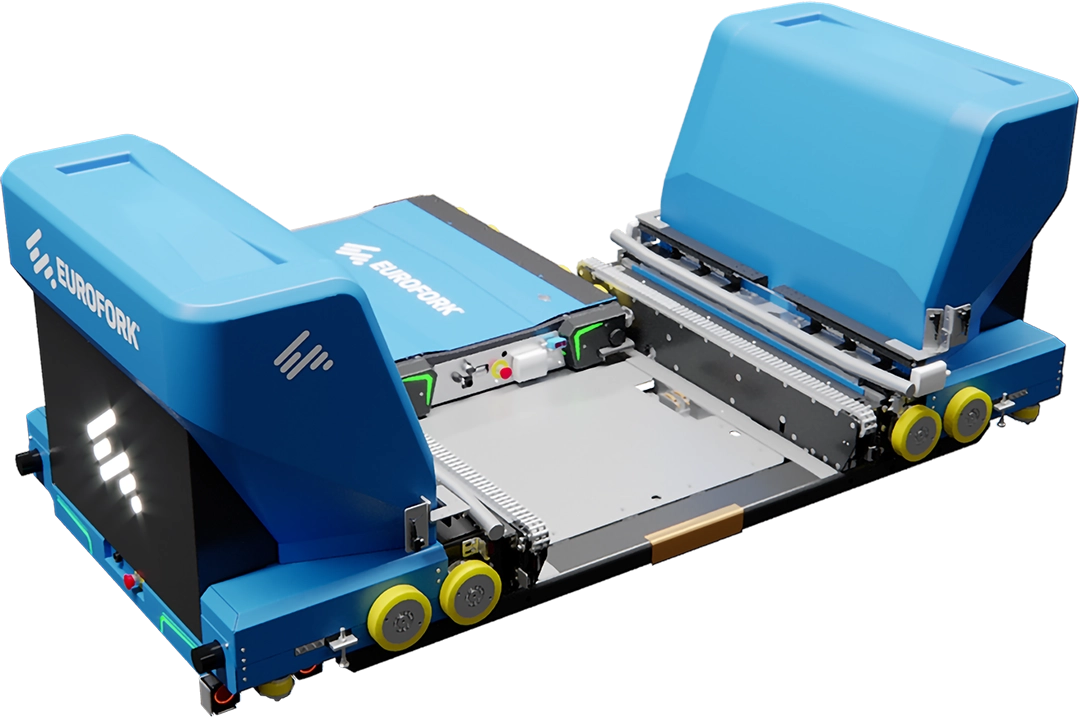

The technology at the heart of E4CUBE® is represented by our advanced four-way pallet shuttle, E4SHUTTLE, integrated within the warehouse structure. Developed based on the 40 million kilometers traveled by the ESMARTSHUTTLE® pallet shuttle, E4SHUTTLE incorporates internationally patented technologies such as absolute positioning and blockchain tracking, ensuring excellent and superior performance, thus guaranteeing an extremely efficient and reliable warehouse management.

E4CUBE® is also supported by the EXA platform, Eurofork’s advanced WCS software platform, which allows for the optimization of all goods flows and pallet shuttle missions. EXA offers intuitive controls and robust features powered by AI technology, revolutionizing warehouse management and ensuring optimal control and continuous optimization of operations.

Forget the limits of traditional automatic warehouses. The incredible turnover rate of E4CUBE®, ranging from 17 to 737, allows for the entire warehouse to be emptied or filled over 700 times in a working year. This operational flexibility translates into dynamic resource management, optimizing turnover rates and maximizing productivity.

E4CUBE® guarantees savings of up to 55% on the total cost of ownership (TCO), ensuring highly efficient financial management. E4CUBE® is also available for lease (operational or financial) with no upfront payment, allowing for immediate access and an excellent return on investment. This arrangement significantly reduces expenses compared to traditional solutions, improving long-term operating costs and offering excellent ROIC.

E4CUBE®, thanks to the reduced volume and weight of the E4SHUTTLE pallet shuttles that handle the load units, offers exceptional energy efficiency, reducing consumption by up to 80% compared to traditional solutions. Furthermore, this solution emits less CO2 than other warehouse automation systems. The CO2 emissions of E4CUBE® are offset by purchasing Carbon Credits from UN-certified entities, making it the greenest automation solution on the market.

The technology at the heart of E4CUBE® is represented by our advanced four-way pallet shuttle, E4SHUTTLE, integrated within the warehouse structure. Developed based on the 40 million kilometers traveled by the ESMARTSHUTTLE® pallet shuttle, E4SHUTTLE incorporates internationally patented technologies such as absolute positioning and blockchain tracking, ensuring excellent and superior performance, thus guaranteeing an extremely efficient and reliable warehouse management.

E4CUBE® is also supported by the EXA platform, Eurofork’s advanced WCS software platform, which allows for the optimization of all goods flows and pallet shuttle missions. EXA offers intuitive controls and robust features powered by AI technology, revolutionizing warehouse management and ensuring optimal control and continuous optimization of operations.

FAQ

E4CUBE® is the first ever standard automated warehouse for multi-deep pallet storage.

It all depends on how you’re handling pallets today, in general, an E4CUBE in its 100 pallets per hour configuration, grants a five times higher efficiency than a single forklift man-operated.

Yes. The warehouse is designed to integrate with existing management software such as WMS or ERP through the EXA-PLUS control platform, enabling optimization of missions, traceability, and operational flows without requiring major changes to the company’s IT systems.

SUBSCRIBE AND

DISCOVER MORE

Fill in the form to download the brochure

Discover our

Success stories

With over 130,000 applications installed in more than 93 countries, our automatic handling systems are considered among the most reliable in the intralogistics automation landscape.

Our complete solution portfolio responds to any automatic handling need, allowing us to be the ideal partner for System Integrators and offering support as a solution provider for any project.

Discover our success stories!

Contact Us

To request further information, fill out the form. Our sales department is available to help you with your next intralogistics automation project.

Related SOLUTIONS

E4SHUTTLE

E4SHUTTLE is a four-way pallet shuttle that revolutionizes multi-depth storage. It moves in all directions and easily changes both level and aisle, adapting to any warehouse, even with complex layouts. With integrated artificial intelligence, it optimizes costs and energy consumption, offering efficiency and sustainability for logistics automation.

Related SOLUTIONS

E4SHUTTLE

E4SHUTTLE is a four-way pallet shuttle that revolutionizes multi-depth storage. It moves in all directions and easily changes both level and aisle, adapting to any warehouse, even with complex layouts. With integrated artificial intelligence, it optimizes costs and energy consumption, offering efficiency and sustainability for logistics automation.

Related SOLUTIONS

E4SHUTTLE

E4SHUTTLE is a four-way pallet shuttle that revolutionizes multi-depth storage. It moves in all directions and easily changes both level and aisle, adapting to any warehouse, even with complex layouts. With integrated artificial intelligence, it optimizes costs and energy consumption, offering efficiency and sustainability for logistics automation.

Related Services

Exa platform

Innovative and smart, Eurofork’s WCS technology platform is the core of our advanced automation solutions. You can also benefit from a complete “turnkey” package that includes consulting, analysis, commissioning, testing, training, and 24/7 support. All are provided with precision by the Eurofork software team.

Eurofork

solutions

Portfolio

Reliability, innovation, and high performance: these are the qualities that make our automated handling systems the ideal choice for improving the efficiency of your warehouse or production line.

With a comprehensive range of solutions designed for every need, we offer cutting-edge technologies to maximize productivity and optimize space.

Discover the complete portfolio