Automated Pallet Shuttle for High-Density Warehouses

0

global patents

up to

0

%energy consumption compared to traditional solutions

up to

0

double cycles per hour

Master

pallet shuttle

system

Master

pallet shuttle

system

master

pallet shuttle

system

Maximum efficiency in high-density automated storage systems

Maximum efficiency in high-density automated storage systems

INTENSIVE STORAGE

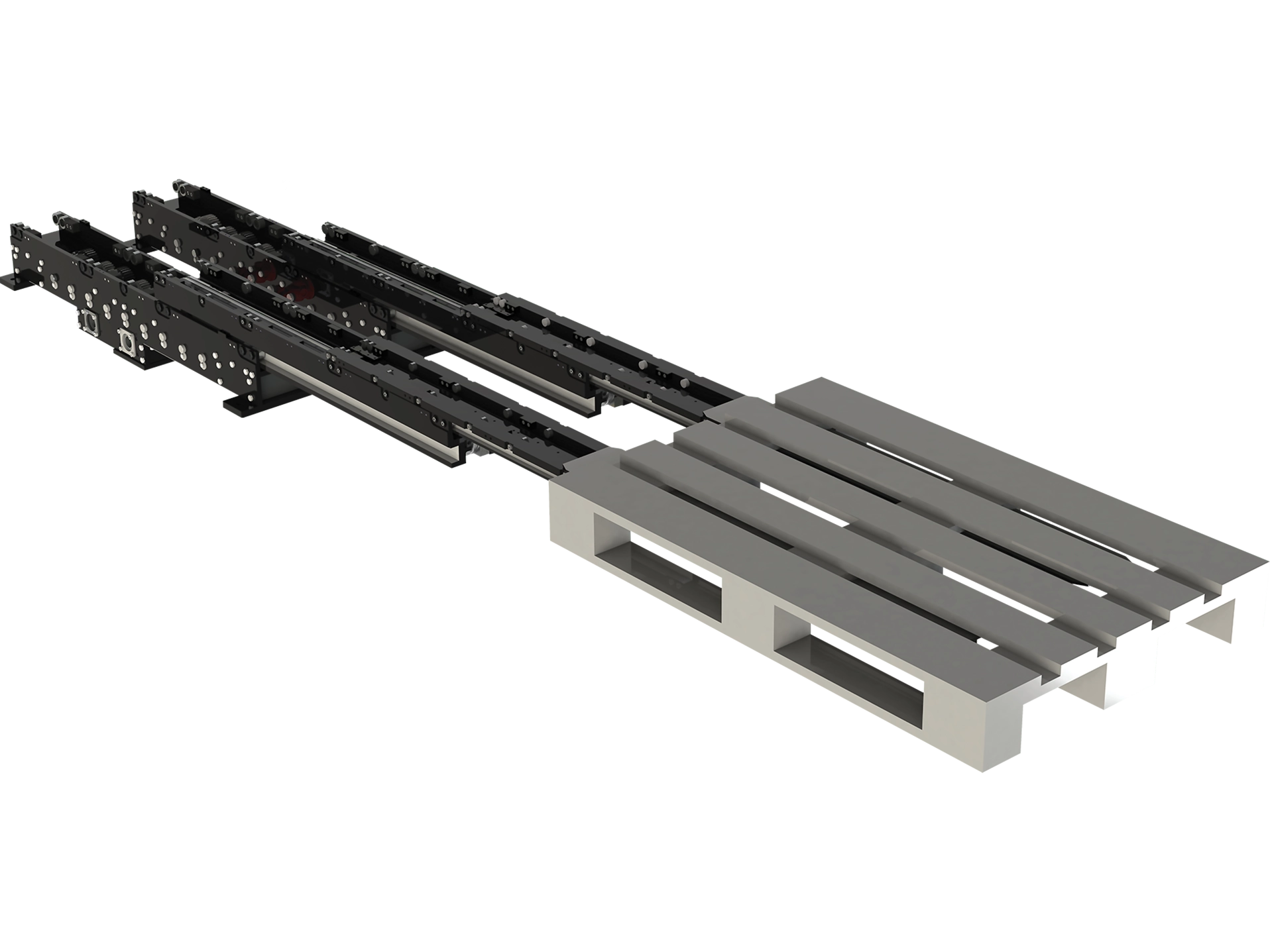

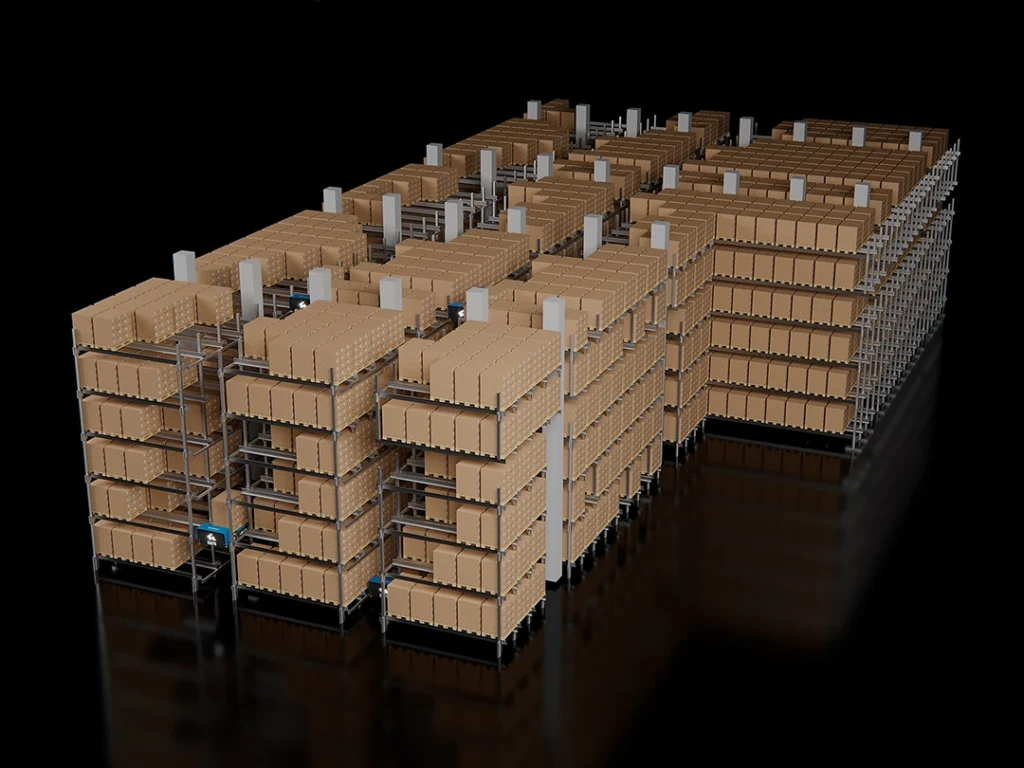

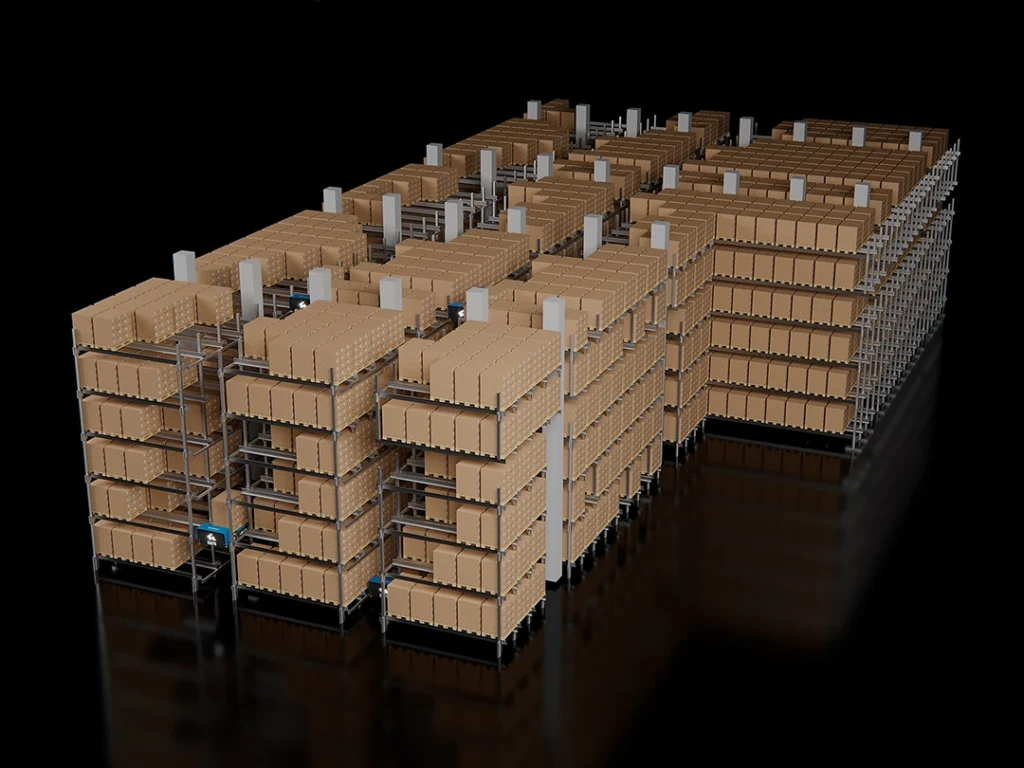

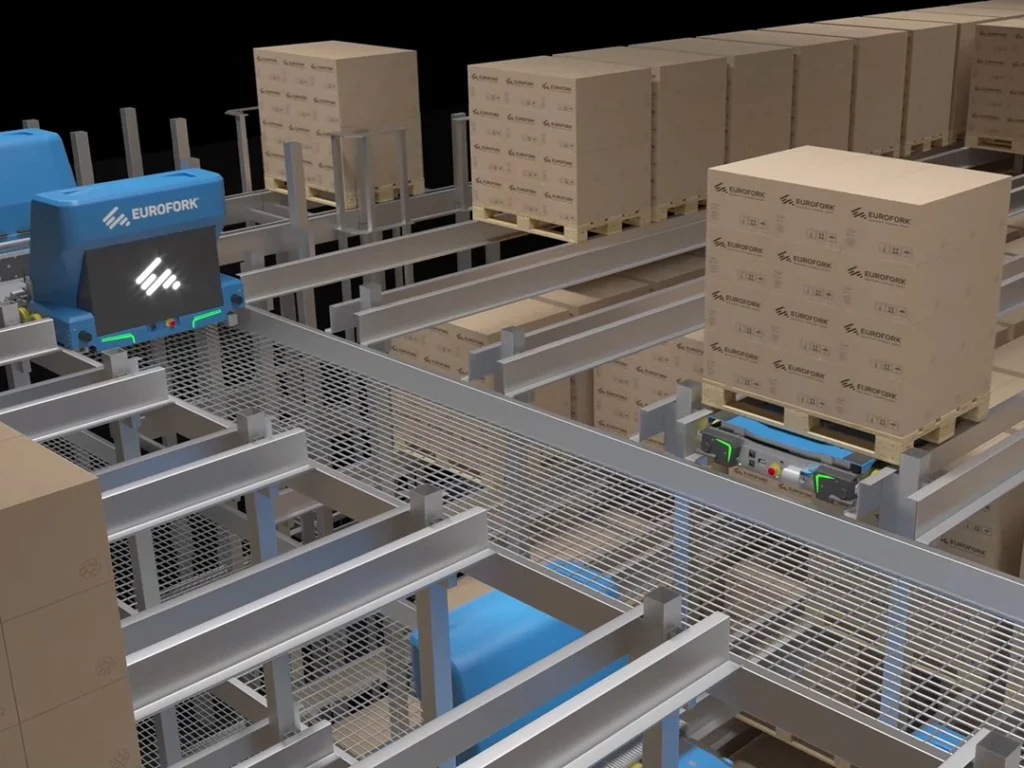

The ESMARTSHUTTLE® pallet shuttle system is the ideal solution for intensive multi-reference pallet storage in automated ASRS warehouses and production buffers. Thanks to its international patents, ESMARTSHUTTLE® offers high storage density and unmatched performance, with the ability to manage incoming and outgoing pallets through independent shuttle and satellite missions.

1.000 TURNS AROUND THE WORLD

With over 40 million kilometers traveled and 3.7 trillion QR codes scanned, ESMARTSHUTTLE® represents an innovative and proven solution in the field of automated storage. Custom-designed to meet customer needs, this system offers unparalleled reliability, operating continuously even in complex environments. The precision and performance of ESMARTSHUTTLE® make it an ideal solution for ensuring efficiency in automated warehouses.

TOTAL EFFICIENCY AND PRECISION

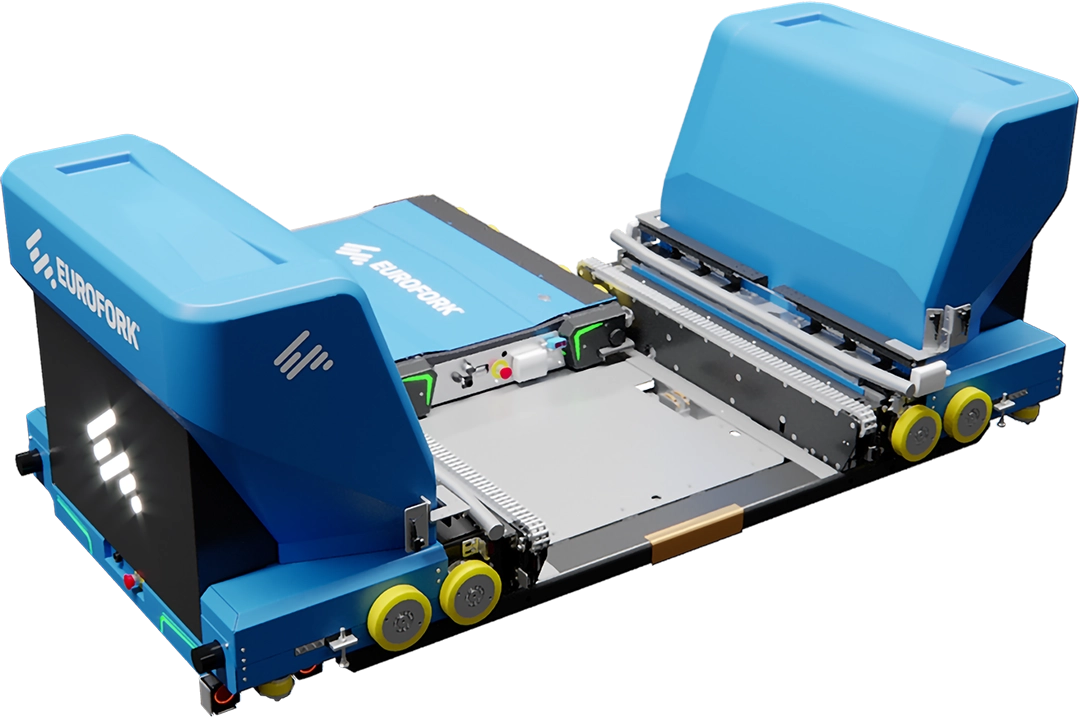

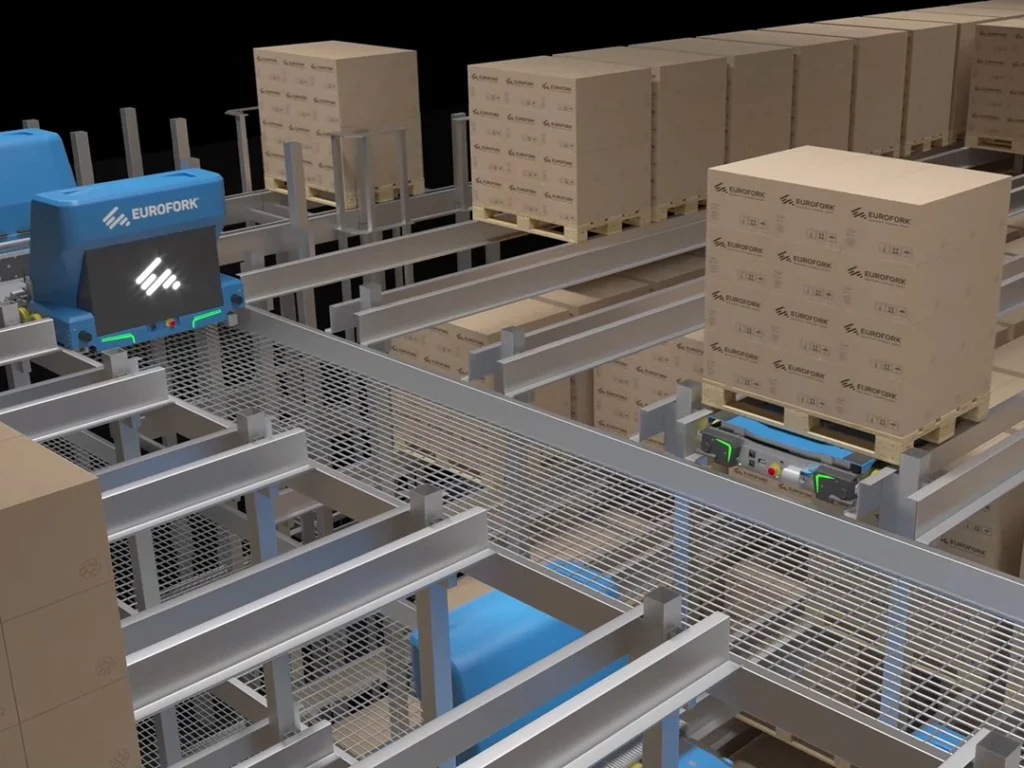

ESMARTSHUTTLE® is the ideal solution for intensive multi-reference storage in automated warehouses and production buffers, ensuring reliable 24/7 performance. Composed of E-SHUTTLE and E-SATELLITE, this system is designed to maximize storage capacity while operating with high precision and continuous flow. The patented technology allows for independent missions and optimizes space, revolutionizing warehouse operations.

ESMARTSHUTTLE

ESMARTSHUTTLE® is the scalable solution that revolutionizes warehouse management. Designed to operate in extreme thermal conditions, from -30°C to +40°C (-22°F to 104°F), and with heavier loads than standard—up to 2000 kg (4400 lb) —it adapts to warehouses in any sector, regardless of size or layout complexity. Its modularity allows for maximizing available space, optimizing automation costs, and improving the overall system performance, even in existing facilities with limitations.

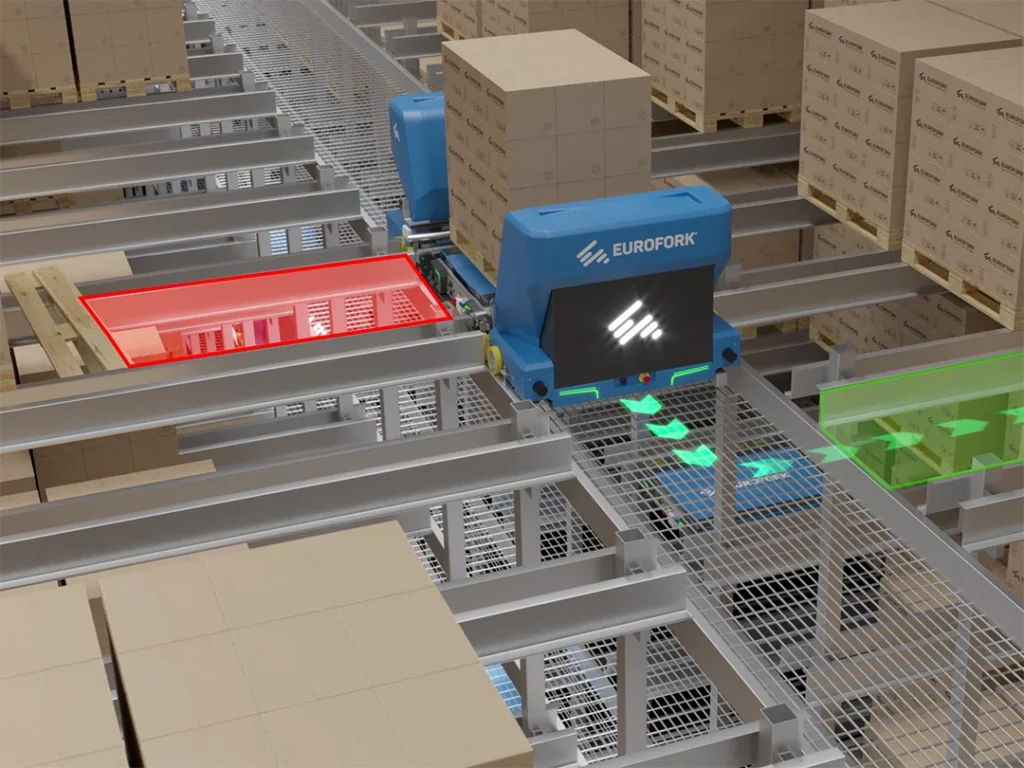

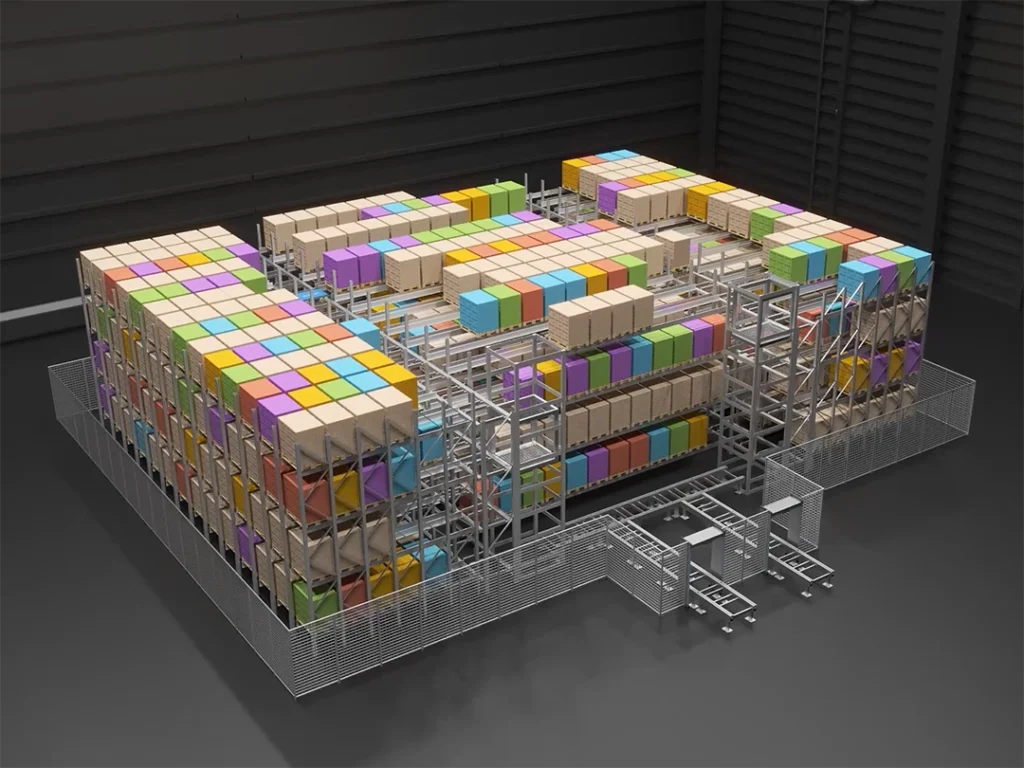

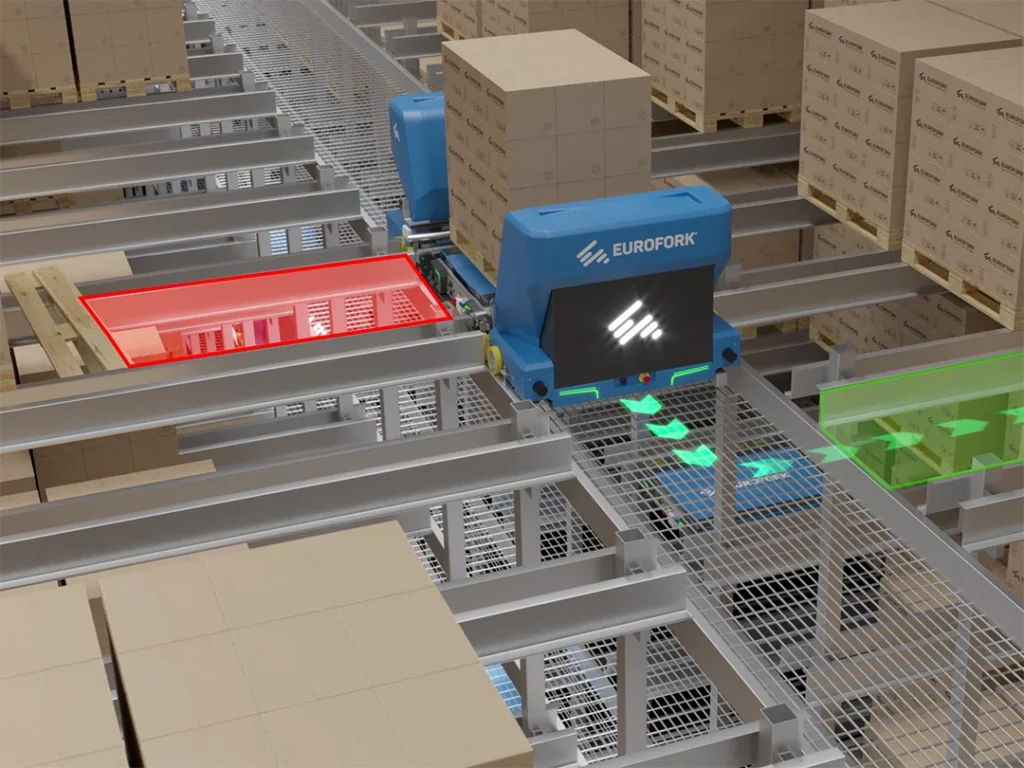

Thanks to its international patent, ESMARTSHUTTLE® guarantees the absolute positioning of machines and the destination of loads. Utilizing a detailed 3D map of the entire warehouse, ESMARTSHUTTLE® moves and stores pallets with unparalleled precision, optimizing every millimeter of available space. With a compact positioning that allows for up to 100 pallet positions per channel, efficiency and storage capacity are maximized, reducing waste and costs.

Thanks to absolute positioning, ESMARTSHUTTLE® can perform independent missions, maximizing warehouse performance. The E-SHUTTLE can operate simultaneously alongside multiple E-SATELLITES, ensuring a continuous intensive flow of storage operations. To further increase warehouse flows, multiple ESMARTSHUTTLE® units can operate in the same storage aisle. With these features, ESMARTSHUTTLE® represents the best solution for improving the performance of any automated warehouse. Additionally, the intensive storage flow is accompanied by extraordinary volumetric optimization, reducing land costs and vertical dimensions.

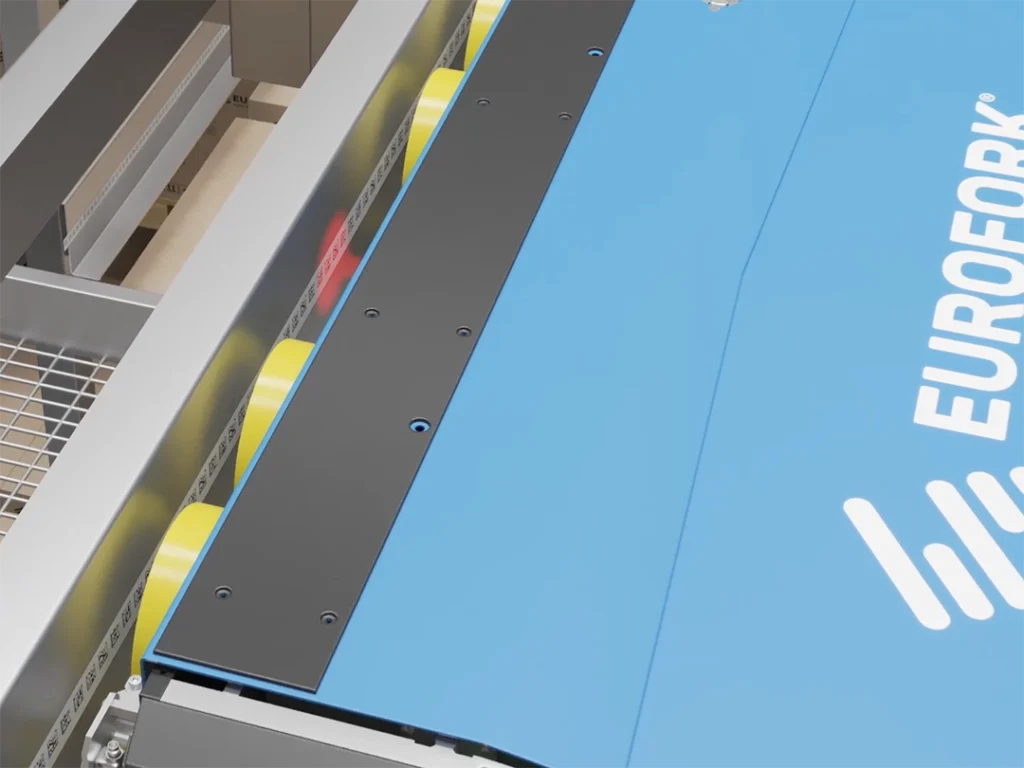

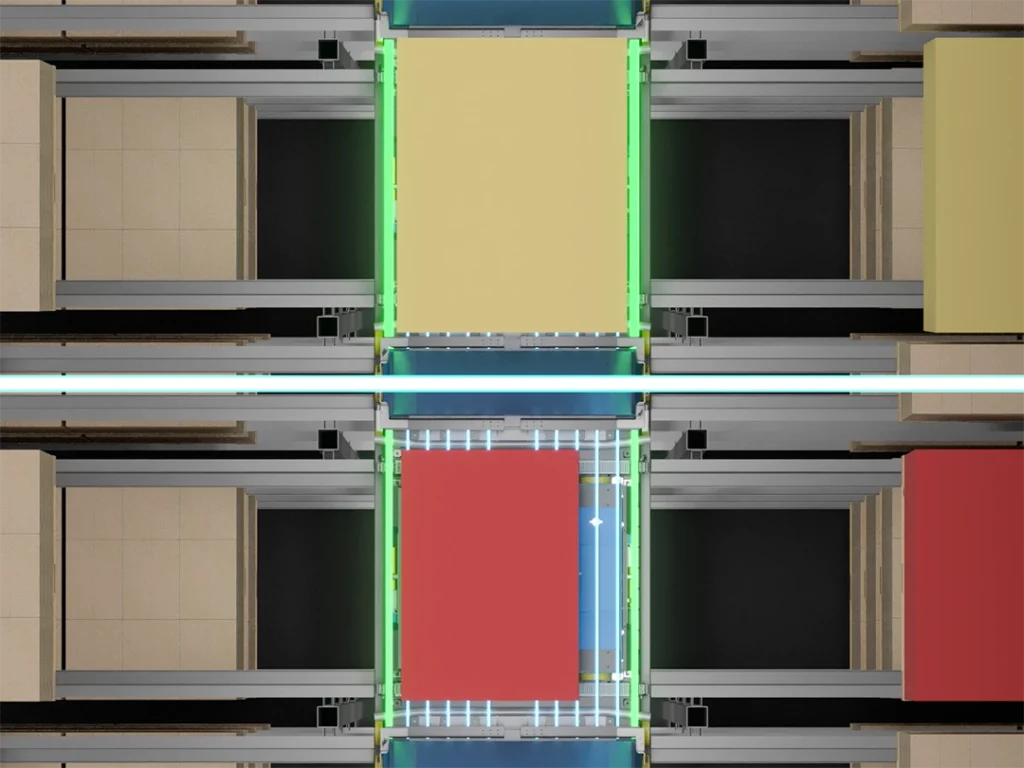

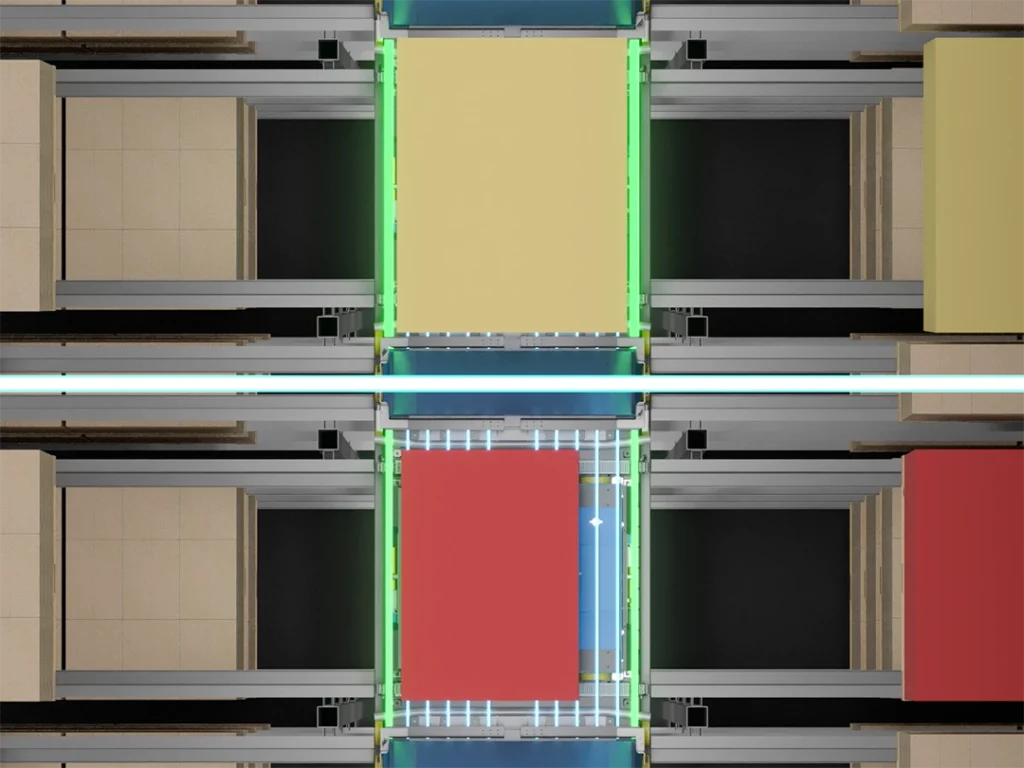

The dedicated system network of ESMARTSHUTTLE® ensures a reliable, powerful, and stable connection thanks to 5 GHz Wi-Fi communication. The state-of-the-art lithium battery of the satellite, which recharges in masked times, allows ESMARTSHUTTLE® to utilize positioning with Datamatrix, confirming it as the only pallet shuttle capable of regularly performing independent missions.

The ESMARTSHUTTLE® system, integrated with EXA and PLC, automatically detects any anomalies during the transport of pallets, such as damage or misalignments. In the event of detection, EXA and PLC immediately react to restore the mission. If the anomaly persists, the system blocks the affected channel and automatically redirects the pallet, ensuring smooth and continuous operations without human intervention, optimizing warehouse productivity.

The remote-adjustable I/O light barrier system of ESMARTSHUTTLE® allows for the management of storage for load units of various sizes, including overhangs, ensuring stability during transport and optimizing space in the aisles. Additionally, it offers the ability to customize the storage logic for each aisle, ensuring maximum flexibility in management.

Maintenance intervals are managed intelligently, calculating cycles, missions, and working times for each machine, ensuring precise interventions based on actual usage. Automatic lubrication units further simplify maintenance and extend the lifespan of the machines. The system also supports predictive maintenance, anticipating potential issues through data and analysis, with real-time notifications for non-urgent actions, maintaining operational efficiency.

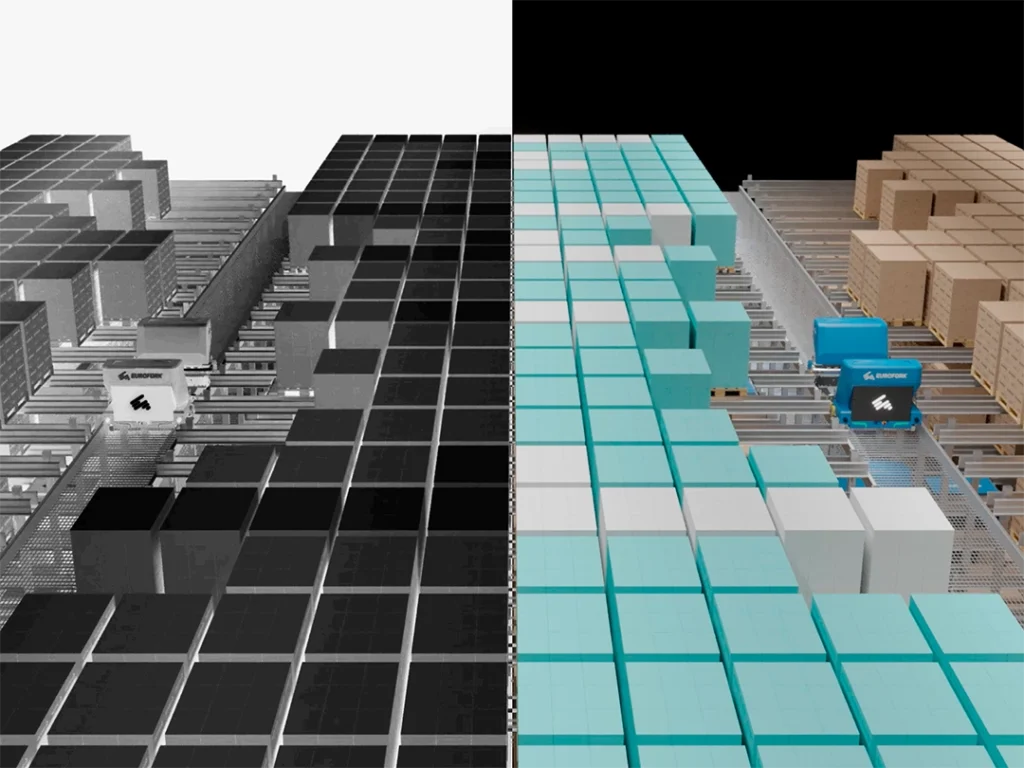

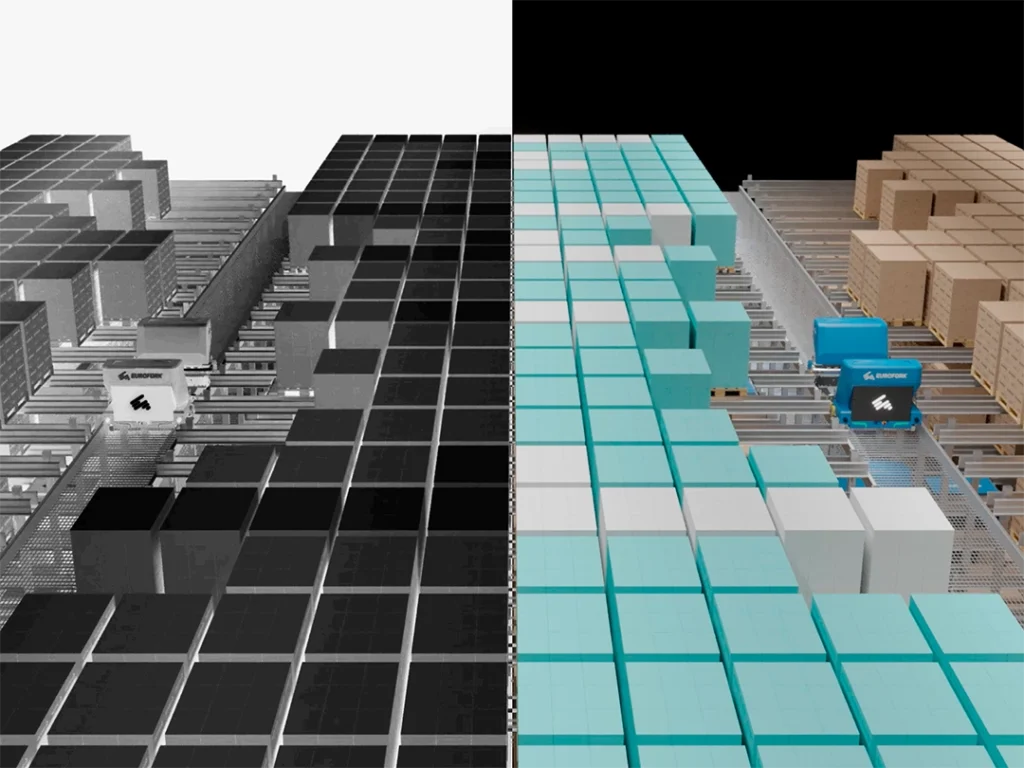

Thanks to the creation of a Digital Twin, Eurofork can virtually replicate the system to test data flows and exchanges before implementation. This technology allows for reduced commissioning time and costs, improving the efficiency and reliability of the system. In addition, it enables in-depth data analysis, mitigating the risk of downtime, optimizing processes, and ensuring seamless operational integration and system continuity.

ESMARTSHUTTLE® is the scalable solution that revolutionizes warehouse management. Designed to operate in extreme thermal conditions, from -30°C to +40°C (-22°F to 104°F), and with heavier loads than standard—up to 2000 kg (4400 lb) —it adapts to warehouses in any sector, regardless of size or layout complexity. Its modularity allows for maximizing available space, optimizing automation costs, and improving the overall system performance, even in existing facilities with limitations.

Thanks to its international patent, ESMARTSHUTTLE® guarantees the absolute positioning of machines and the destination of loads. Utilizing a detailed 3D map of the entire warehouse, ESMARTSHUTTLE® moves and stores pallets with unparalleled precision, optimizing every millimeter of available space. With a compact positioning that allows for up to 100 pallet positions per channel, efficiency and storage capacity are maximized, reducing waste and costs.

Thanks to absolute positioning, ESMARTSHUTTLE® can perform independent missions, maximizing warehouse performance. The E-SHUTTLE can operate simultaneously alongside multiple E-SATELLITES, ensuring a continuous intensive flow of storage operations. To further increase warehouse flows, multiple ESMARTSHUTTLE® units can operate in the same storage aisle. With these features, ESMARTSHUTTLE® represents the best solution for improving the performance of any automated warehouse. Additionally, the intensive storage flow is accompanied by extraordinary volumetric optimization, reducing land costs and vertical dimensions.

The dedicated system network of ESMARTSHUTTLE® ensures a reliable, powerful, and stable connection thanks to 5 GHz Wi-Fi communication. The state-of-the-art lithium battery of the satellite, which recharges in masked times, allows ESMARTSHUTTLE® to utilize positioning with Datamatrix, confirming it as the only pallet shuttle capable of regularly performing independent missions.

The ESMARTSHUTTLE® system, integrated with EXA and PLC, automatically detects any anomalies during the transport of pallets, such as damage or misalignments. In the event of detection, EXA and PLC immediately react to restore the mission. If the anomaly persists, the system blocks the affected channel and automatically redirects the pallet, ensuring smooth and continuous operations without human intervention, optimizing warehouse productivity.

The remote-adjustable I/O light barrier system of ESMARTSHUTTLE® allows for the management of storage for load units of various sizes, including overhangs, ensuring stability during transport and optimizing space in the aisles. Additionally, it offers the ability to customize the storage logic for each aisle, ensuring maximum flexibility in management.

Maintenance intervals are managed intelligently, calculating cycles, missions, and working times for each machine, ensuring precise interventions based on actual usage. Automatic lubrication units further simplify maintenance and extend the lifespan of the machines. The system also supports predictive maintenance, anticipating potential issues through data and analysis, with real-time notifications for non-urgent actions, maintaining operational efficiency.

Thanks to the creation of a Digital Twin, Eurofork can virtually replicate the system to test data flows and exchanges before implementation. This technology allows for reduced commissioning time and costs, improving the efficiency and reliability of the system. In addition, it enables in-depth data analysis, mitigating the risk of downtime, optimizing processes, and ensuring seamless operational integration and system continuity.

SUBSCRIBE AND

DISCOVER MORE

Fill in the form to download the brochure

Discover our

Success stories

With over 130,000 applications installed in more than 93 countries, our automatic handling systems are considered among the most reliable in the intralogistics automation landscape.

Our complete solution portfolio responds to any automatic handling need, allowing us to be the ideal partner for System Integrators and offering support as a solution provider for any project.

Discover our success stories!

Contact us

To request further information, fill out the form. Our sales department is available to help you with your next intralogistics automation project.

DO YOU ALREADY HAVE ALL THE NECESSARY DATA?

If you already have all the data for your next project, click the button and send us the quote request!

Related SOLUTIONS

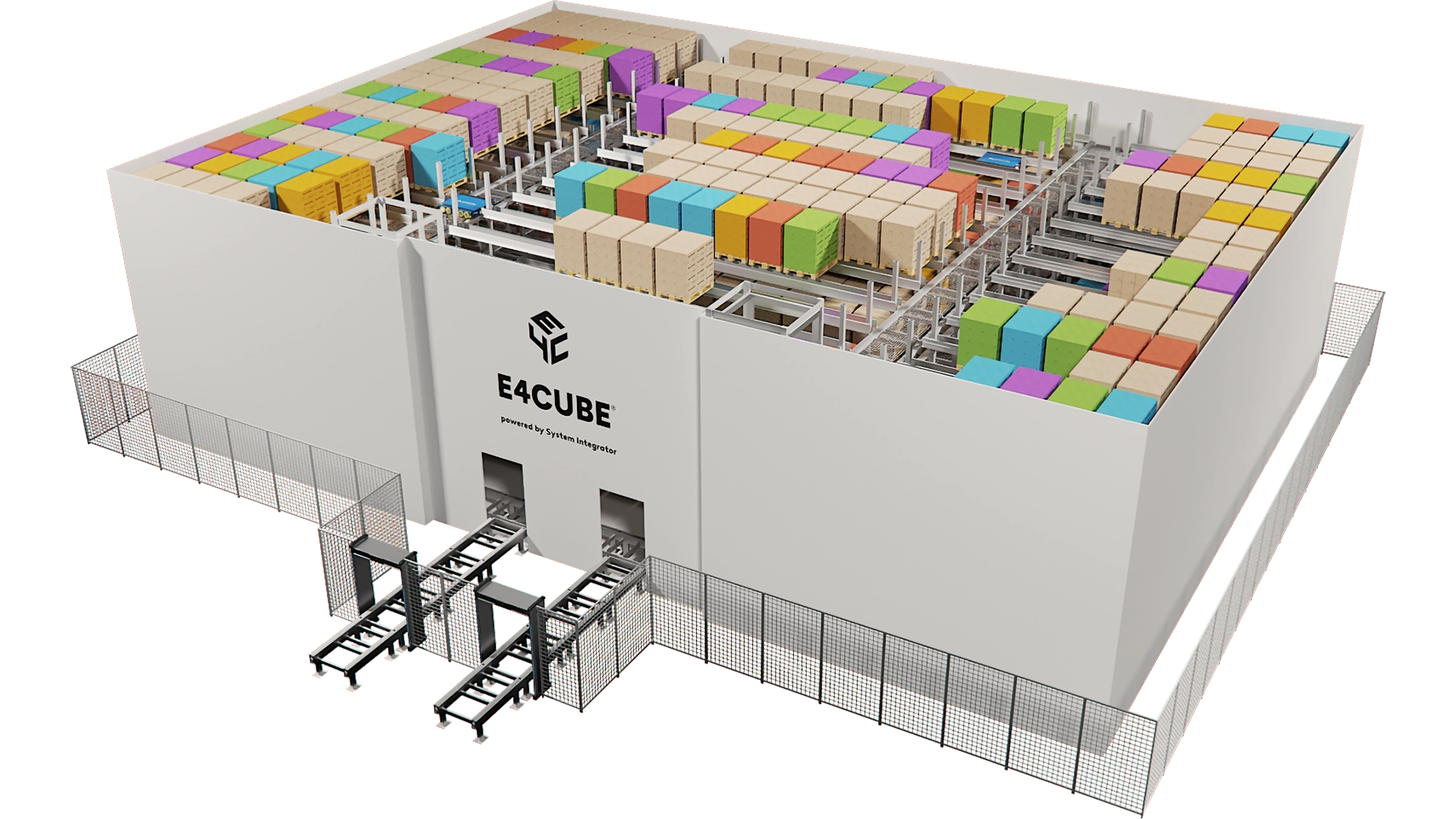

E4SHUTTLE

E4SHUTTLE is a four-way pallet shuttle that revolutionizes multi-depth storage. It moves in all directions and easily changes both level and aisle, adapting to any warehouse, even with complex layouts. With integrated artificial intelligence, it optimizes costs and energy consumption, offering efficiency and sustainability for logistics automation.

Related SOLUTIONS

E4SHUTTLE

E4SHUTTLE is a four-way pallet shuttle that revolutionizes multi-depth storage. It moves in all directions and easily changes both level and aisle, adapting to any warehouse, even with complex layouts. With integrated artificial intelligence, it optimizes costs and energy consumption, offering efficiency and sustainability for logistics automation.

Related SOLUTIONS

E4SHUTTLE

E4SHUTTLE is a four-way pallet shuttle that revolutionizes multi-depth storage. It moves in all directions and easily changes both level and aisle, adapting to any warehouse, even with complex layouts. With integrated artificial intelligence, it optimizes costs and energy consumption, offering efficiency and sustainability for logistics automation.

Related Services

Exa platform

Innovative and smart, Eurofork’s WCS technology platform is the core of our advanced automation solutions. You can also benefit from a complete “turnkey” package that includes consulting, analysis, commissioning, testing, training, and 24/7 support. All are provided with precision by the Eurofork software team.

Eurofork

solutions

Portfolio

Reliability, innovation, and high performance: these are the qualities that make our automated handling systems the ideal choice for improving the efficiency of your warehouse or production line.

With a comprehensive range of solutions designed for every need, we offer cutting-edge technologies to maximize productivity and optimize space.

Discover the complete portfolio