Telescopic forks

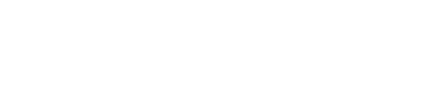

Double deep

Telescopic forks

Double deep

APPLICATION FLEXIBILITY

POSITIONING PRECISION

FULL CUSTOMIZATION

INCREASED STORAGE CAPACITY

ERROR MINIMIZATION

ADAPTABLE FOR USE IN VARIOUS TEMPERATURE CONDITIONS

INTERNATIONALLY PATENTED

LOW DEFLECTION VALUE

HIGH-QUALITY MATERIALS

HIGH RELIABILITY AND EASY MAINTENANCE

COMPACT DIMENSIONS

APPLICATION FLEXIBILITY

POSITIONING PRECISION

FULL CUSTOMIZATION

INCREASED STORAGE CAPACITY

ERROR MINIMIZATION

ADAPTABLE FOR USE IN VARIOUS TEMPERATURE CONDITIONS

INTERNATIONALLY PATENTED

LOW DEFLECTION VALUE

HIGH-QUALITY MATERIALS

HIGH RELIABILITY AND EASY MAINTENANCE

COMPACT DIMENSIONS

APPLICATION FLEXIBILITY

POSITIONING PRECISION

FULL CUSTOMIZATION

INCREASED STORAGE CAPACITY

ERROR MINIMIZATION

ADAPTABLE FOR USE IN VARIOUS TEMPERATURE CONDITIONS

INTERNATIONALLY PATENTED

LOW DEFLECTION VALUE

HIGH-QUALITY MATERIALS

HIGH RELIABILITY AND EASY MAINTENANCE

COMPACT DIMENSIONS

TIMELESS

EXCELLENCE

TIMELESS

EXCELLENCE

TIMELESS

EXCELLENCE

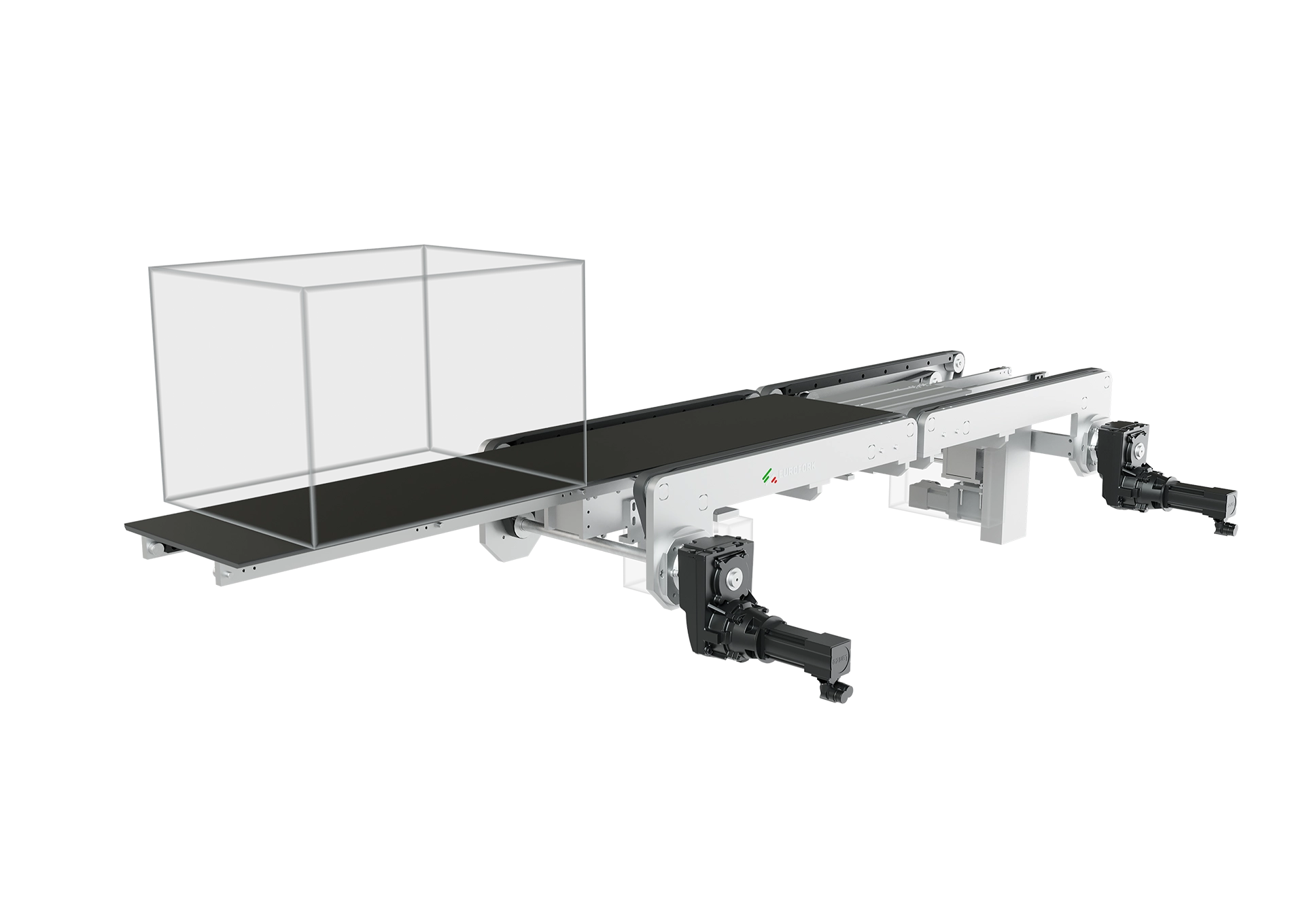

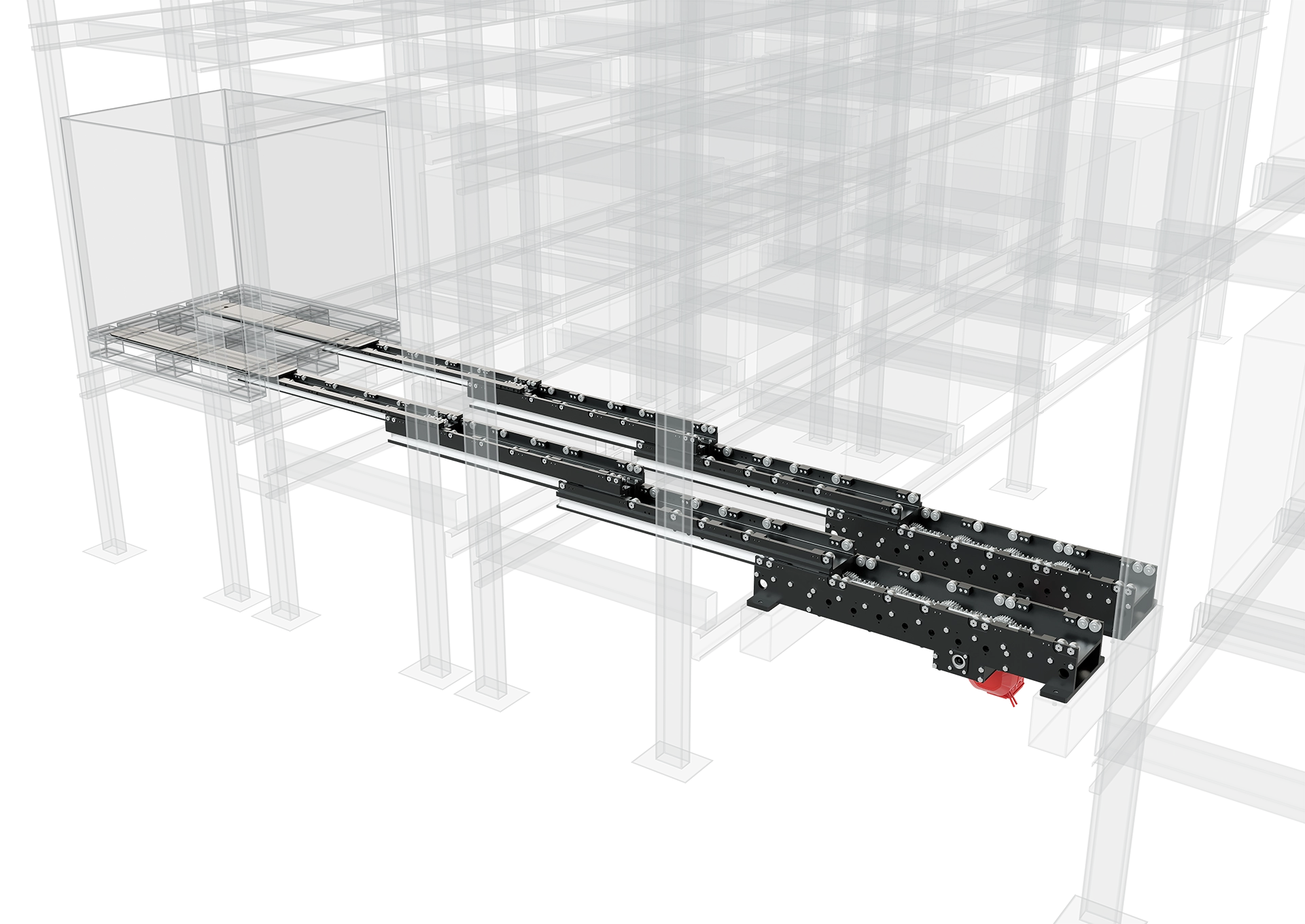

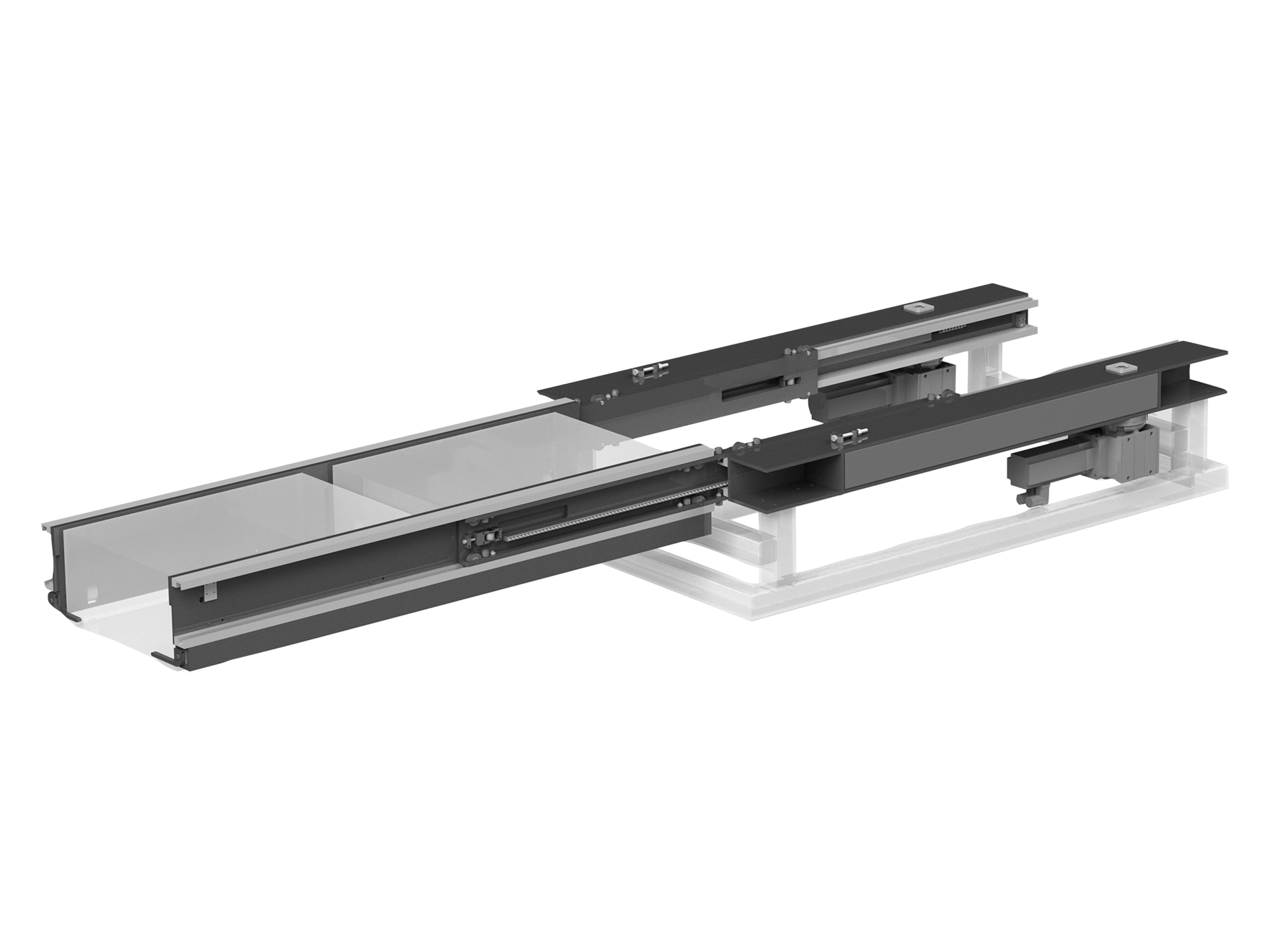

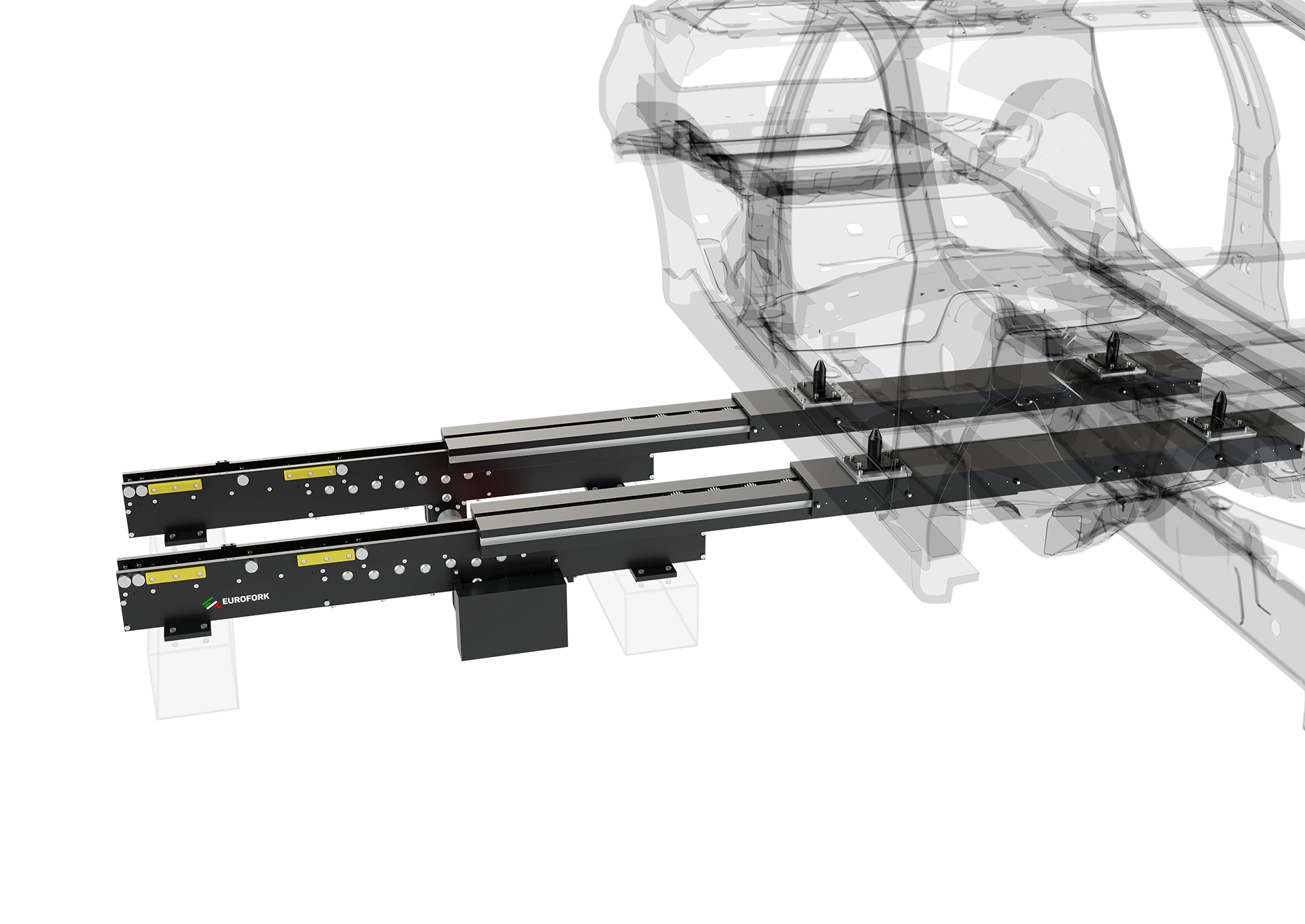

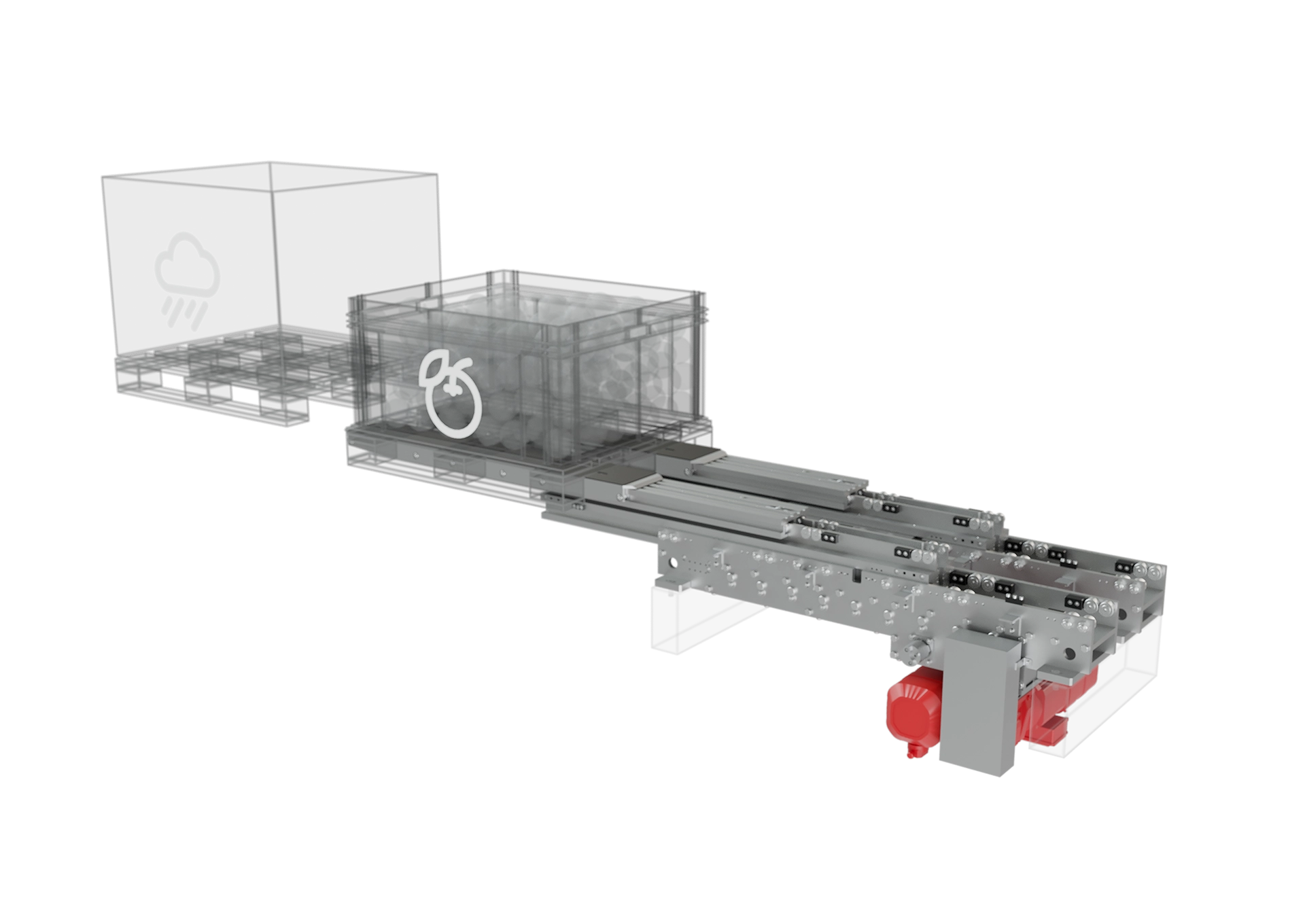

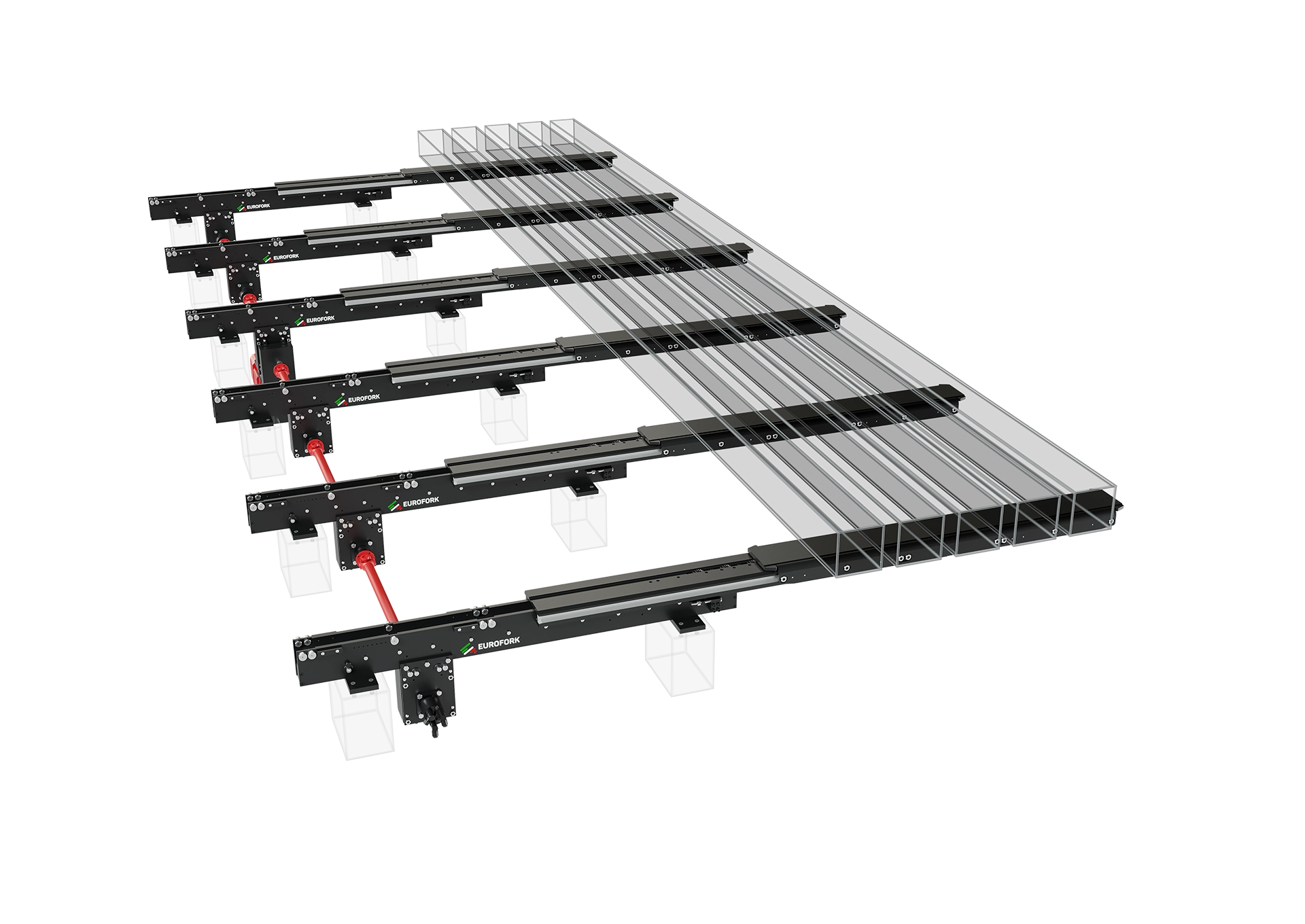

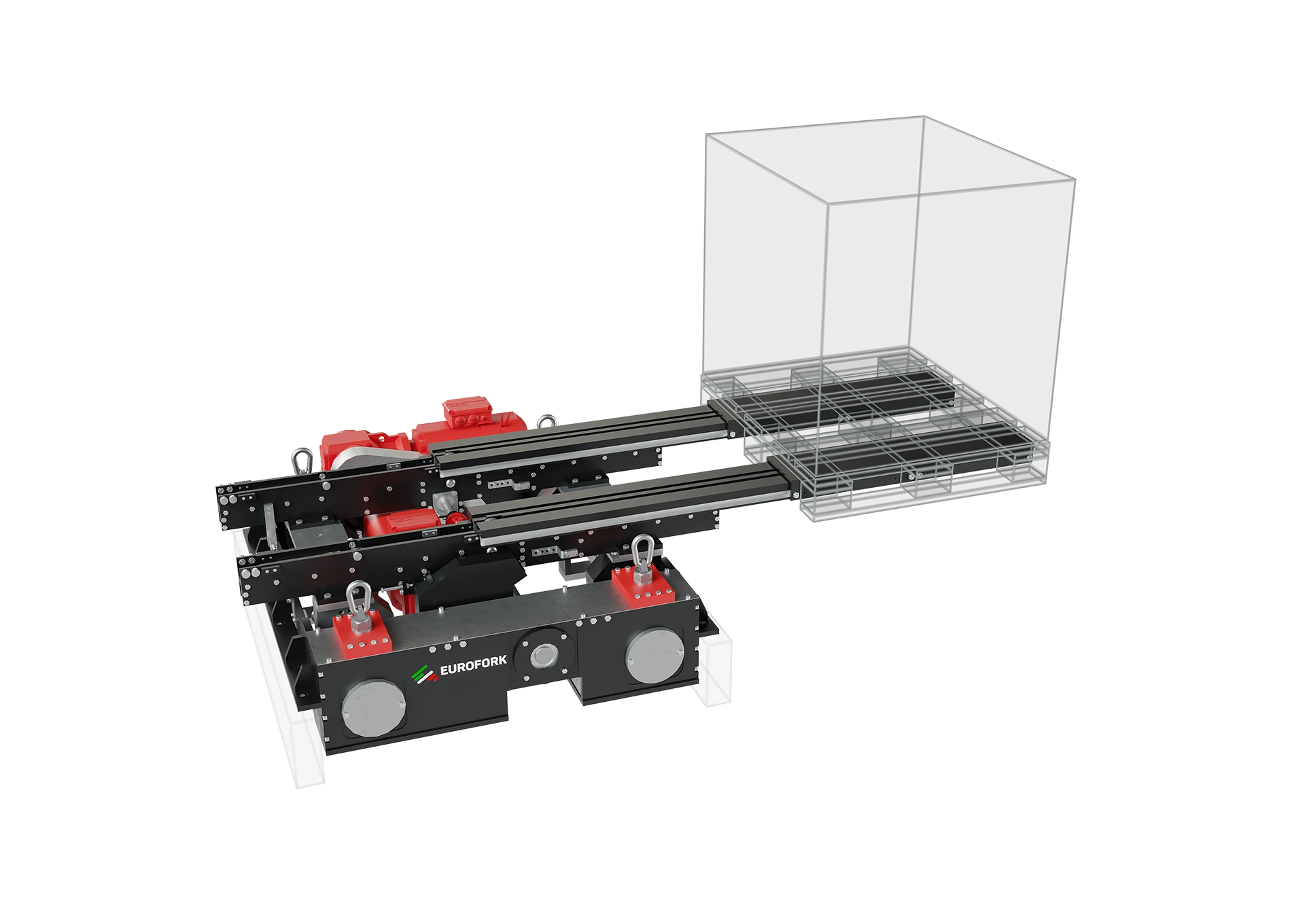

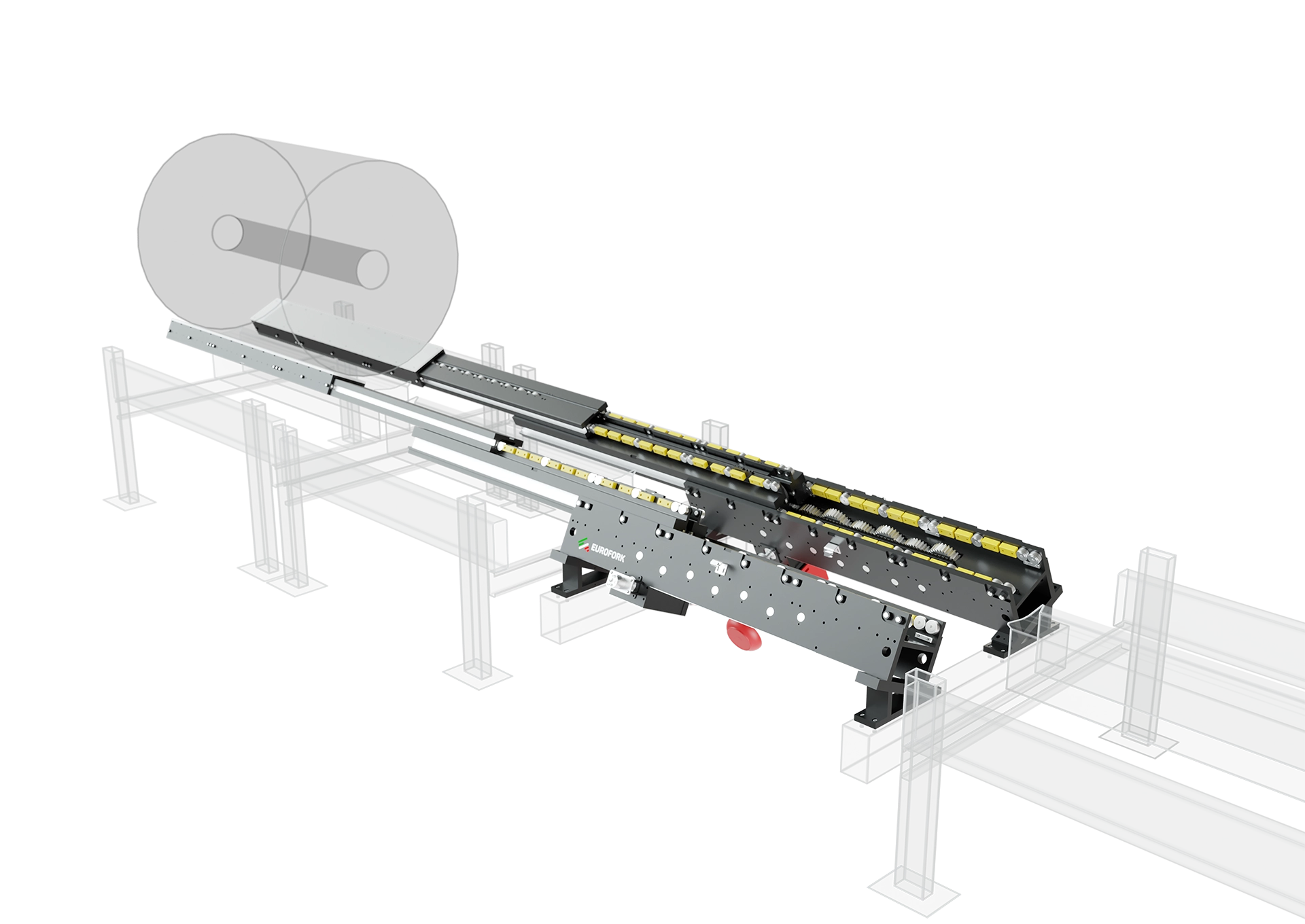

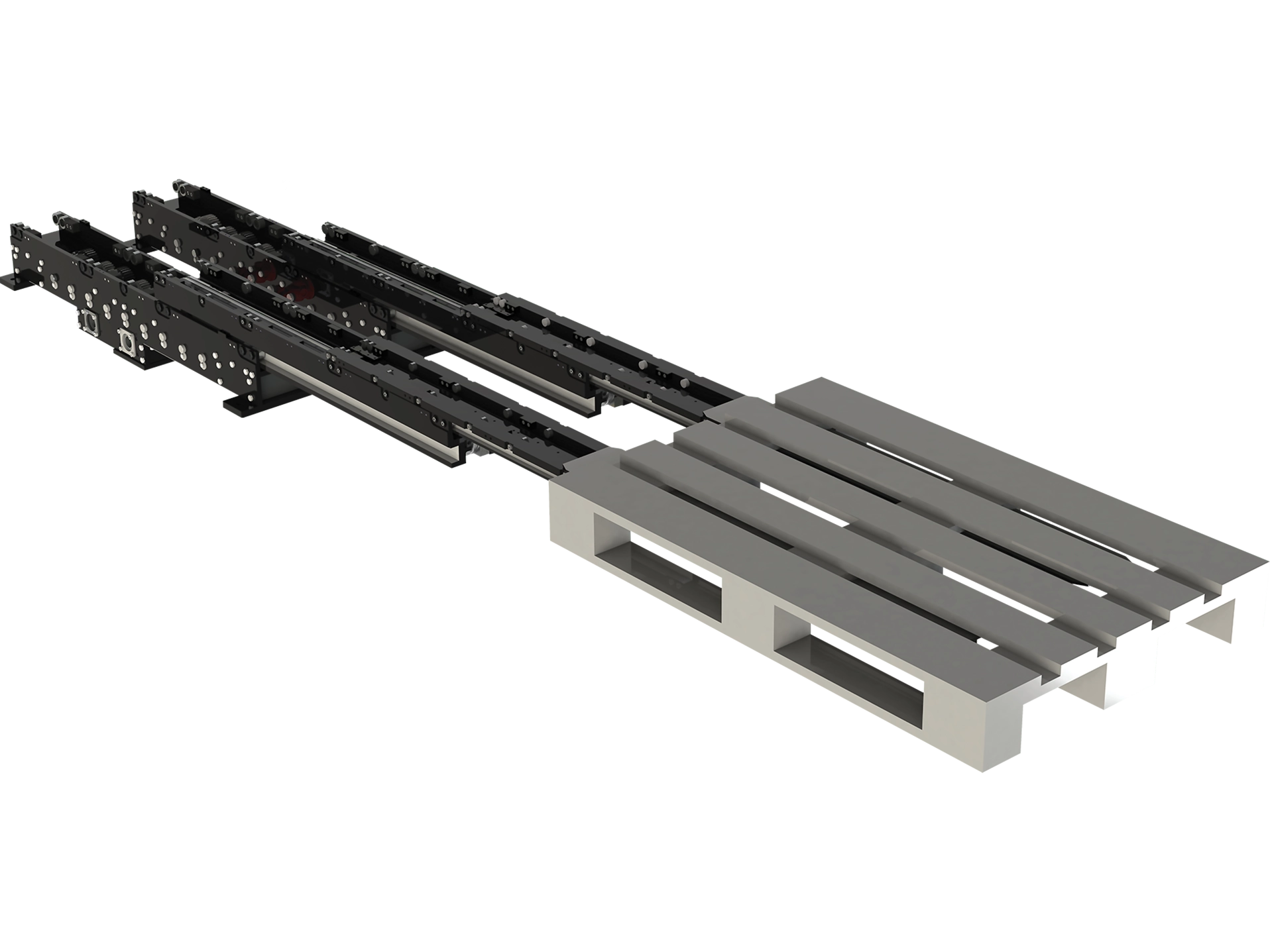

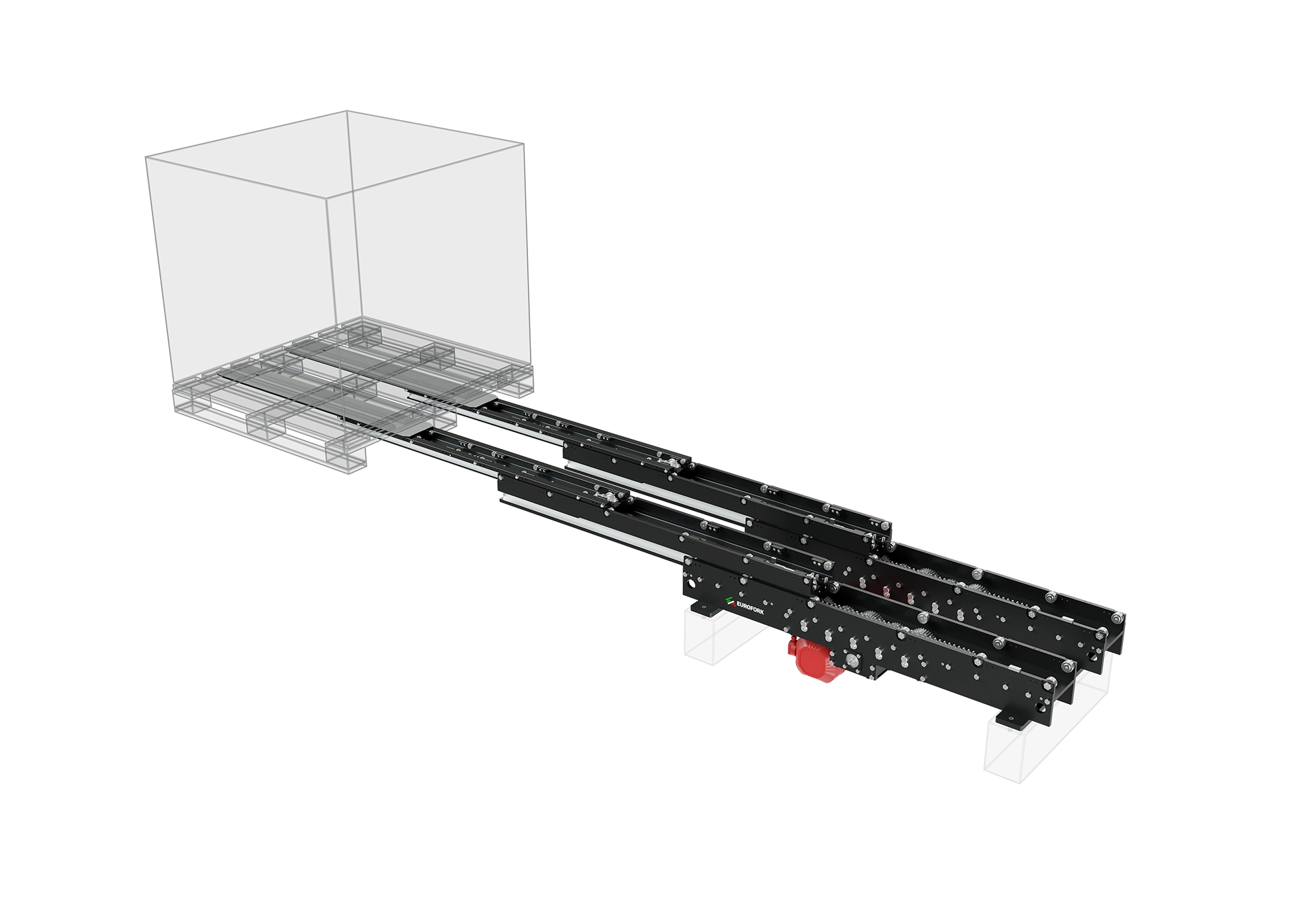

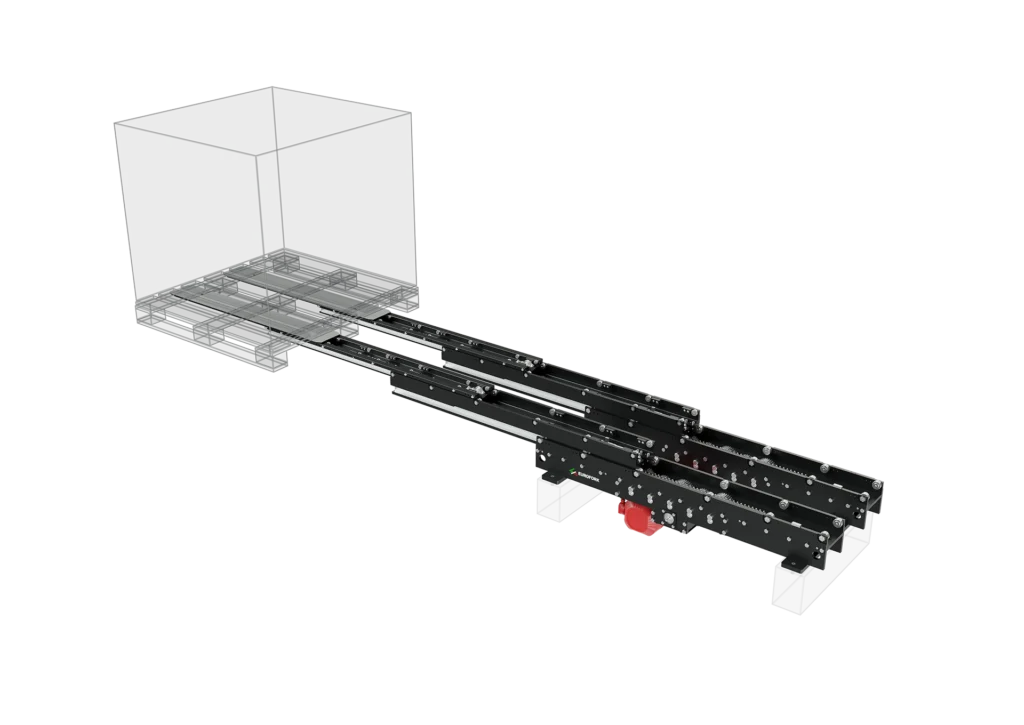

Double-depth telescopic forks maximize space in automated warehouses and beyond. Composed of a fixed body and three moving extensions, these handling devices move unit loads bilaterally up to the second depth of the racking system.

The transmission system of our double-depth forks ensures synchronized movement of all extendable sections.

supplementary systems:

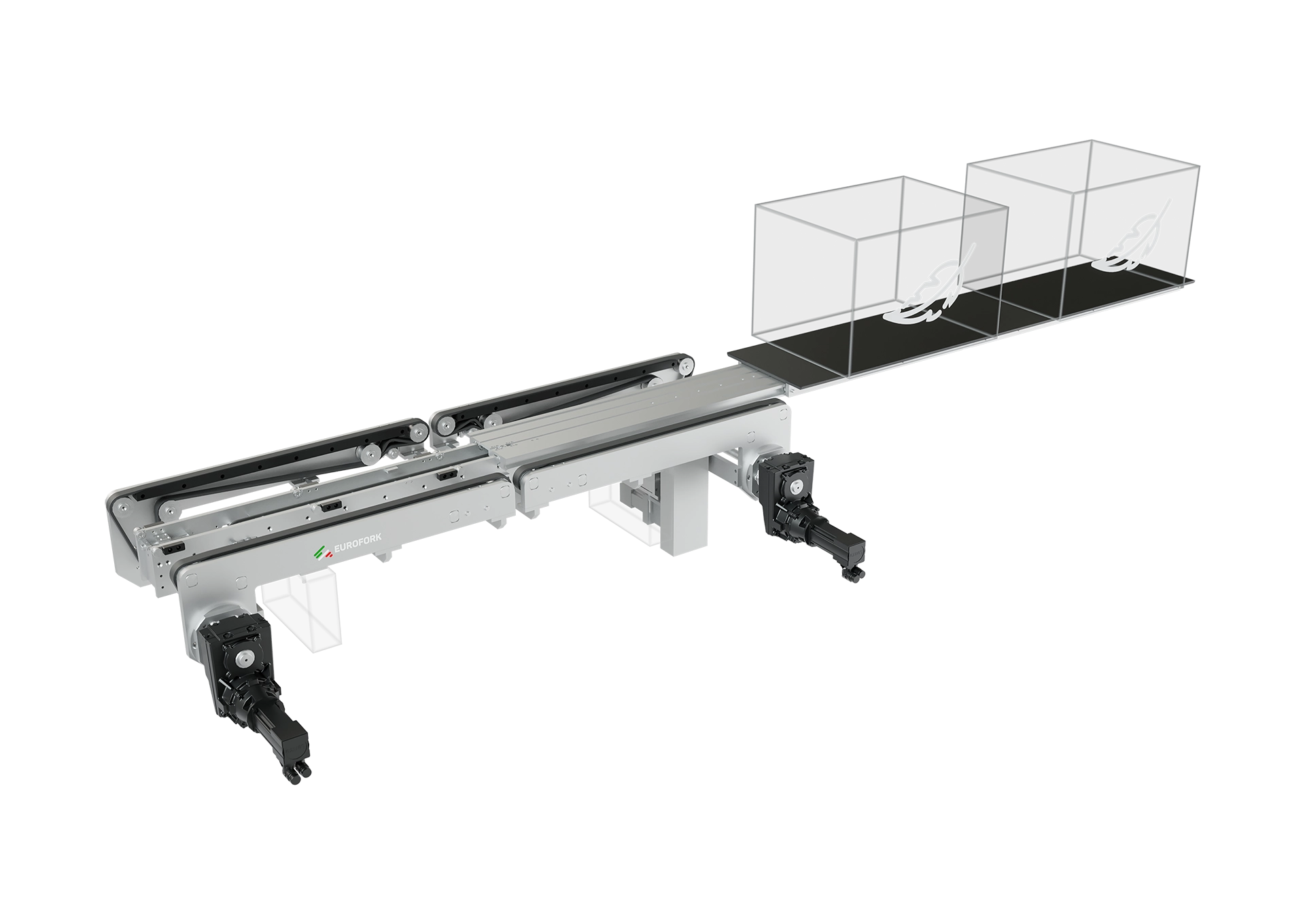

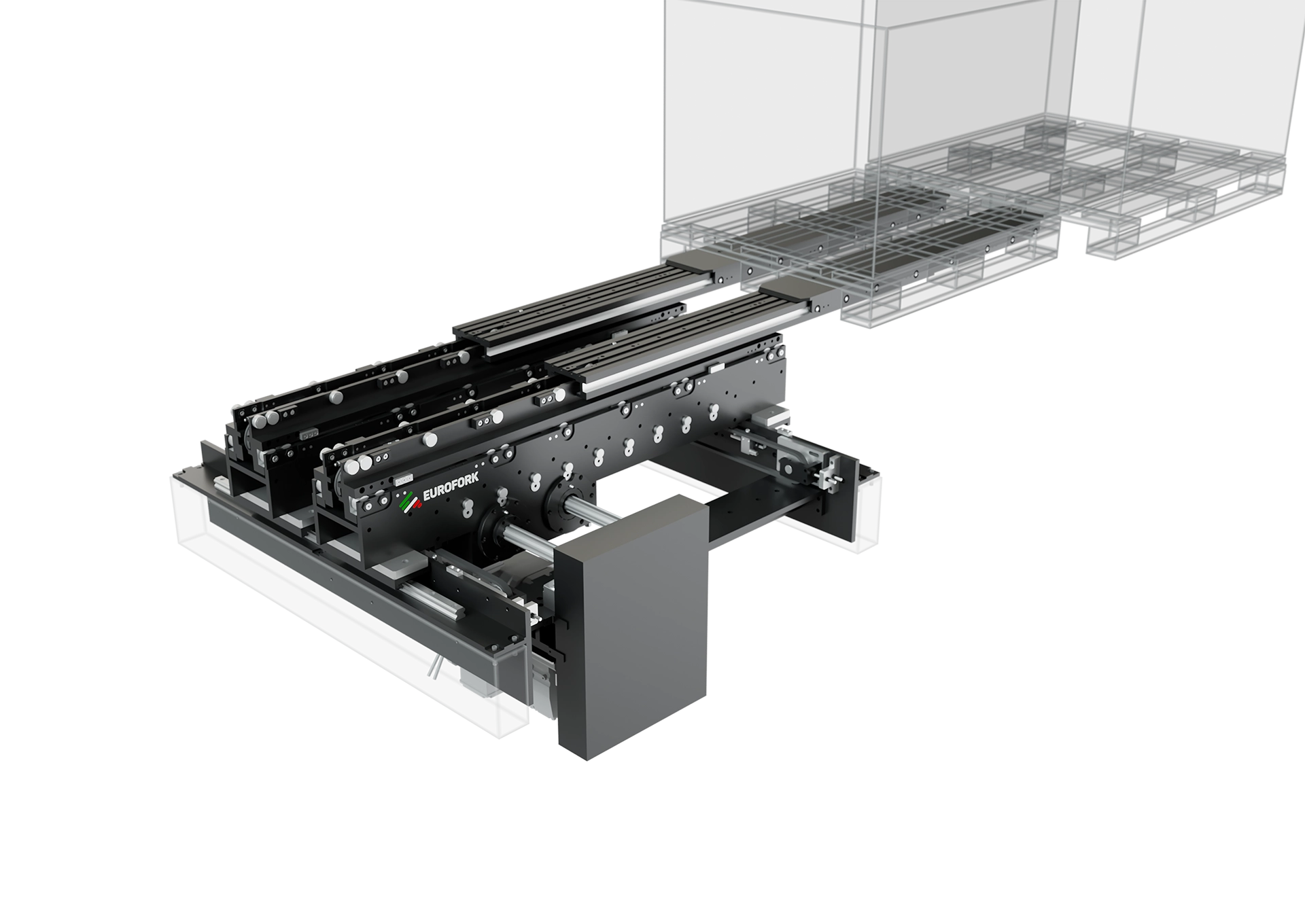

The Variant version of the double-depth telescopic fork offers significant cost savings on the structural design of the AS/RS automated warehouse.

Thanks to dedicated transmissions that independently and dynamically control the extensions, unit loads can be handled with a reduced footprint of moving parts, both in single and double-depth configurations, while also minimizing the height of the moving components.

supplementary systems:

Double-depth telescopic forks maximize space in automated warehouses and beyond. Composed of a fixed body and three moving extensions, these handling devices move unit loads bilaterally up to the second depth of the racking system.

The transmission system of our double-depth forks ensures synchronized movement of all extendable sections.

supplementary systems:

The Variant version of the double-depth telescopic fork offers significant cost savings on the structural design of the AS/RS automated warehouse.

Thanks to dedicated transmissions that independently and dynamically control the extensions, unit loads can be handled with a reduced footprint of moving parts, both in single and double-depth configurations, while also minimizing the height of the moving components.

supplementary systems:

Find the

telescopic fork

designed

for you

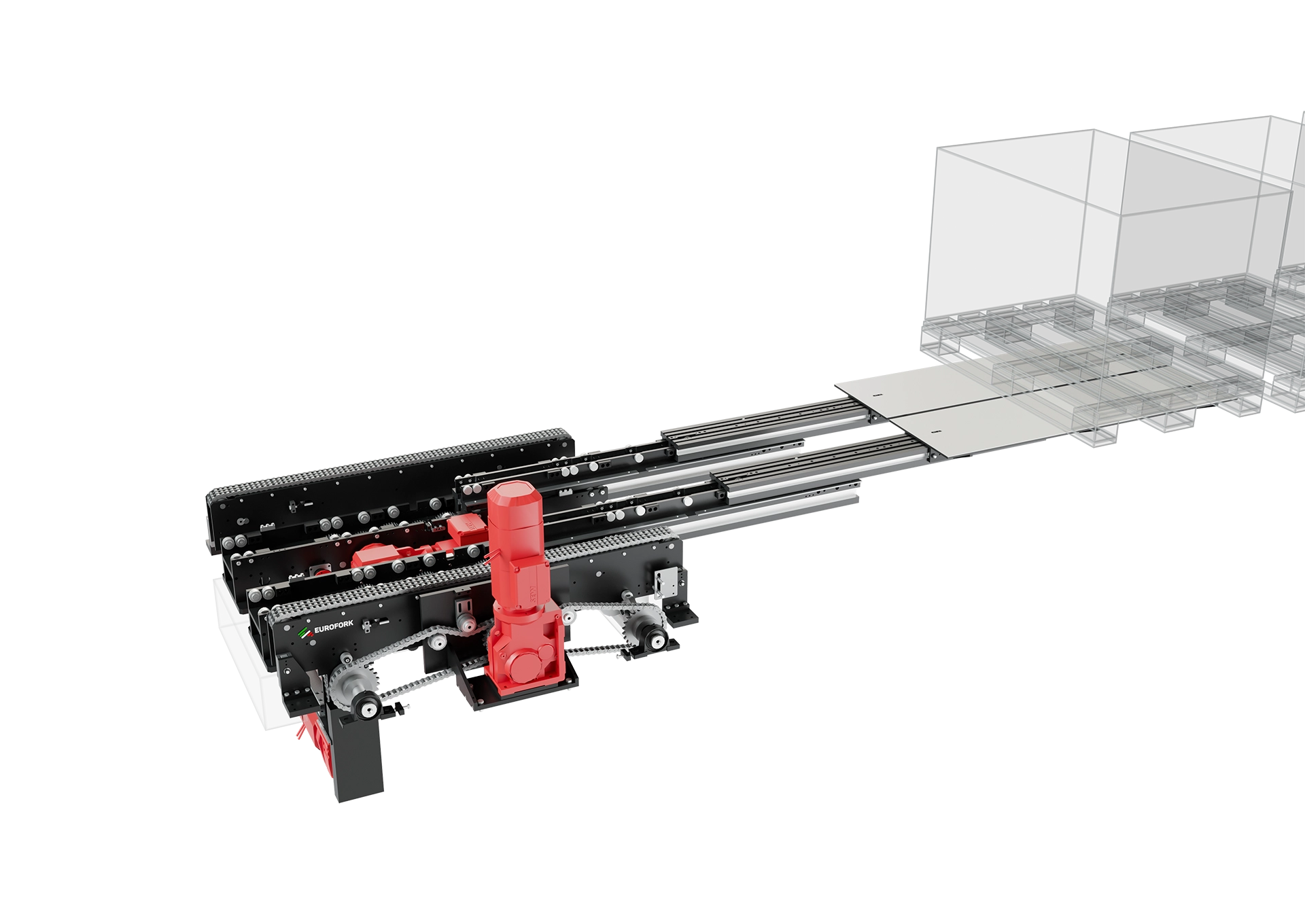

Eurofork telescopic forks are considered the top-class solution for System Integrators worldwide.

We have designed solutions for every load unit and application sector; discover the type of telescopic forks that meet your needs.

COntact us

To request further information, fill out the form. Our sales department is available to help you with your next intralogistics automation project.

DO YOU ALREADY HAVE ALL THE NECESSARY DATA?

If you already have all the data for your next project, click the button and send us the quote request!

Related services

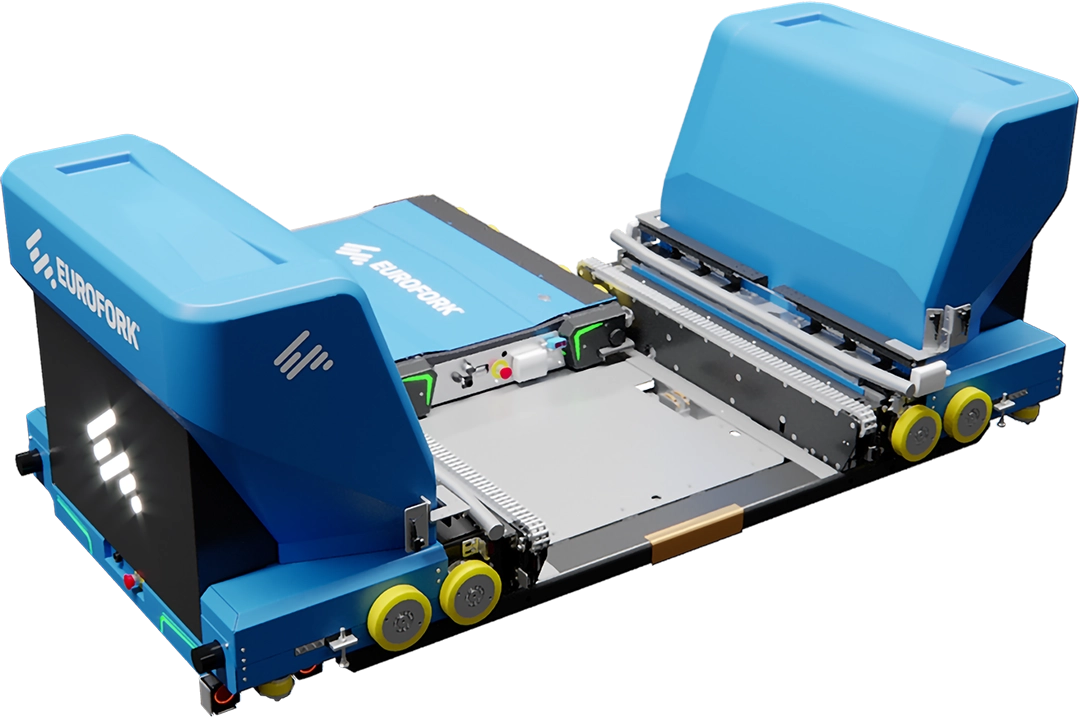

E-SMARTFORKS

Eurofork has leveraged its extensive expertise in automated handling and advanced technology development for 4.0 shuttle systems to create the next evolution in telescopic forks: E-SMARTFORKS. Equipped with IoT devices and sensors from leading global brands, E-SMARTFORKS enable real-time monitoring of telescopic fork status, optimizing maintenance schedules and predicting potential issues from unexpected external events.

Related services

E-SMARTFORKS

Eurofork has leveraged its extensive expertise in automated handling and advanced technology development for 4.0 shuttle systems to create the next evolution in telescopic forks: E-SMARTFORKS. Equipped with IoT devices and sensors from leading global brands, E-SMARTFORKS enable real-time monitoring of telescopic fork status, optimizing maintenance schedules and predicting potential issues from unexpected external events.

Related services

E-SMARTFORKS

Eurofork has leveraged its extensive expertise in automated handling and advanced technology development for 4.0 shuttle systems to create the next evolution in telescopic forks: E-SMARTFORKS. Equipped with IoT devices and sensors from leading global brands, E-SMARTFORKS enable real-time monitoring of telescopic fork status, optimizing maintenance schedules and predicting potential issues from unexpected external events.

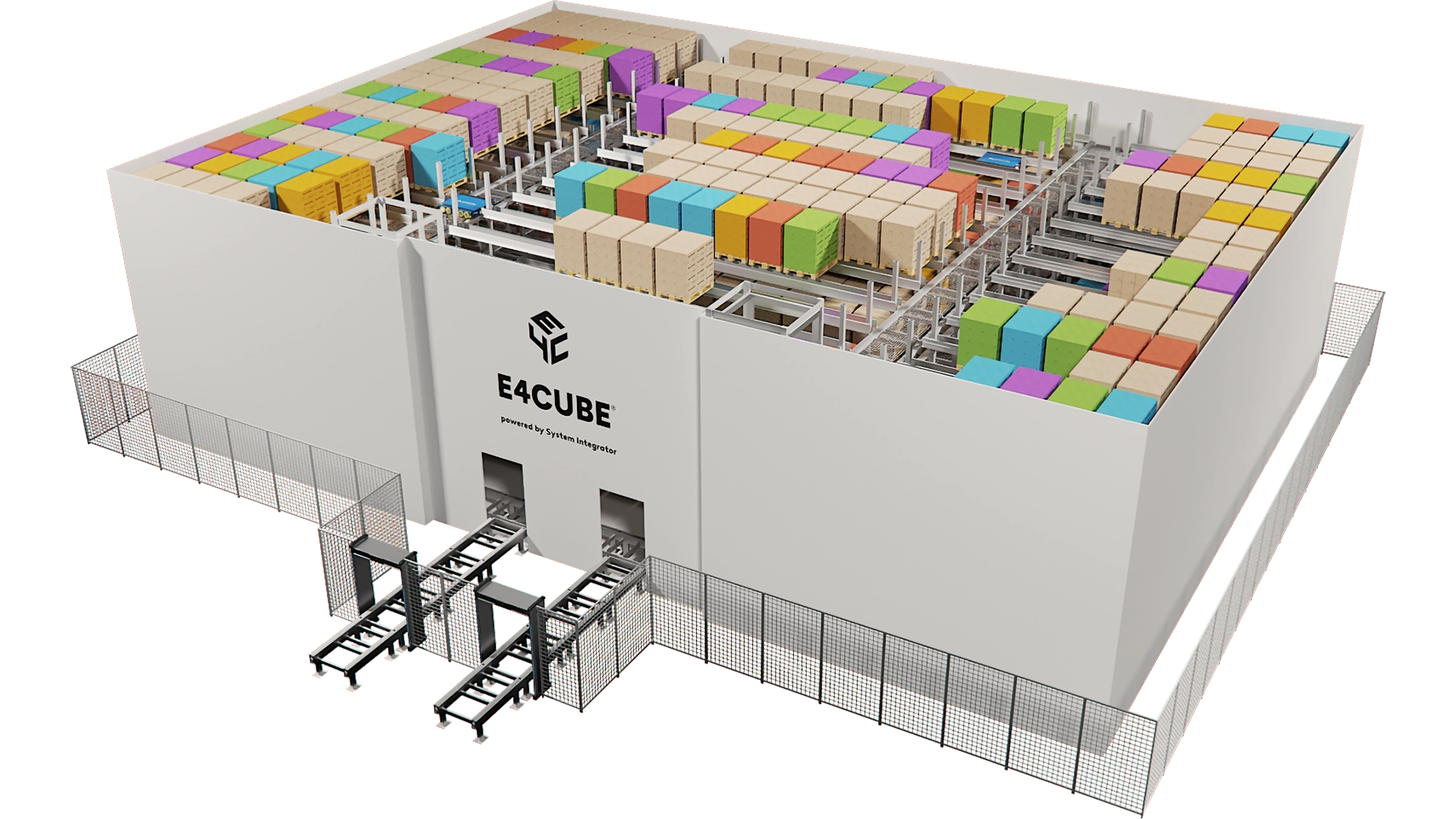

Eurofork

solutions

Portfolio

Reliability, innovation, and high performance: these are the qualities that make our automated handling systems the ideal choice for improving the efficiency of your warehouse or production line.

With a comprehensive range of solutions designed for every need, we offer cutting-edge technologies to maximize productivity and optimize space.

Discover the complete portfolio