E4SHUTTLE

Food&Beverage

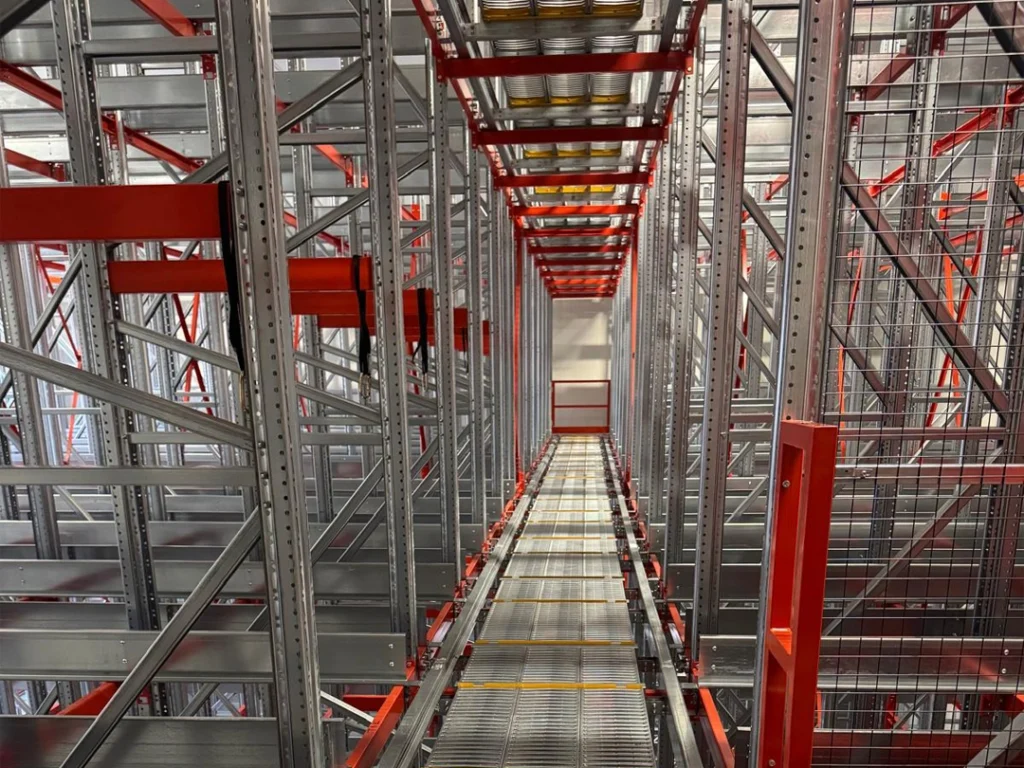

The future of scalability with E4SHUTTLE: the Eurofork® and Linde project

Relying on a manual system to manage the last mile of warehouse operations can lead to inefficiencies and high costs, compromising the quality of fresh products and customer satisfaction. A producer in Northwestern Italy faced this challenge by turning to Linde and Eurofork®. We developed an automated solution to significantly improve performance and ensure that the fruit always arrives fresh and on time to the end user.

Results

FLEXIBILITY AND SCALABILITY OF THE SOLUTION

INCREASED PERFORMANCE AND PALLET PLACES

FOUR LEVEL WAREHOUSE MANAGEMENT

Requirement

Managing pallets, such as EPAL and Industry, with different heights in a temperature-controlled environment between

0 and 5°C (32 – 41°F) and humidity up to 85%, presents a challenge for a warehouse handling perishable goods. Additionally, the client needed to manage variable throughput, with peaks of up to 60 pallets per hour, each weighing up to 1,250 kg. The proposed project, equipped with E4SHUTTLE and lifters for both pallets and shuttles, solved the problem at its core. Thanks to the system’s ability to handle different pallet heights, the throughput became smoother, thus optimizing the efficiency of movements within the cold storage.

Sign up and

Read more

Enter your details to download the full case study