ESMARTSHUTTLE

Food&Beverage

ESMARTSHUTTLE®: SUSTAINABILITY AND OPERATIONAL EFFICIENCY

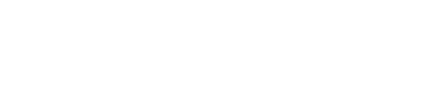

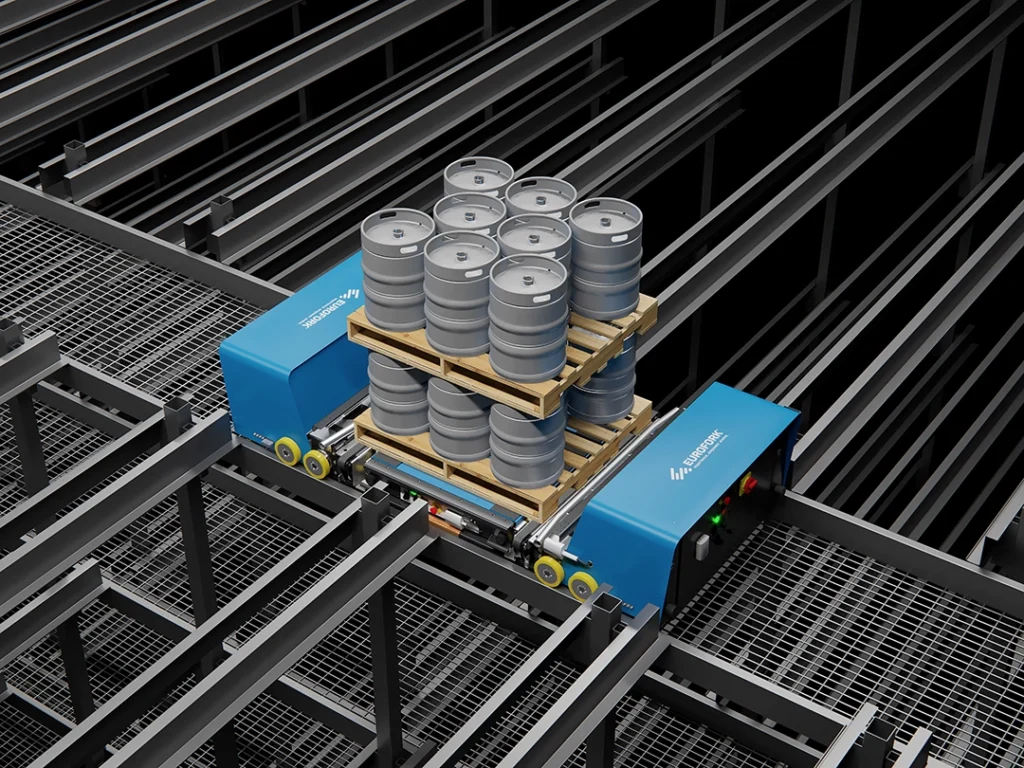

An automated refrigerated warehouse with 20 ESMARTSHUTTLE® systems allowed to optimize of beverage storage, maintaining quality and nutritional values until shipment. For one of the world’s largest alcoholic beverage producers, the risk of deterioration and the costs of third-party logistics providers were high.

Results

40% REDUCTION IN ENERGY CONSUMPTION FOR EACH ESMARTSHUTTLE® MISSION

SAVINGS ON 3PL COSTS

STORAGE IN A REFRIGERATED CELL AND INCREASED PRODUCT SHELF LIFE

Requirement

Managing production and logistics manually in a vast 9,600m2 area not only led to operational inefficiencies but also risked compromising product quality. This situation called for an innovative solution to streamline processes, reduce human error, and maintain product integrity. The solution? An automated refrigerated warehouse within the existing production facility. The flexibility of ESMARTSHUTTLE® allowed for optimized space and storage efficiency while enhancing product preservation and quality.

Sign up and

Read more

Enter your details to download the full case study