E4CUBE

Grocery

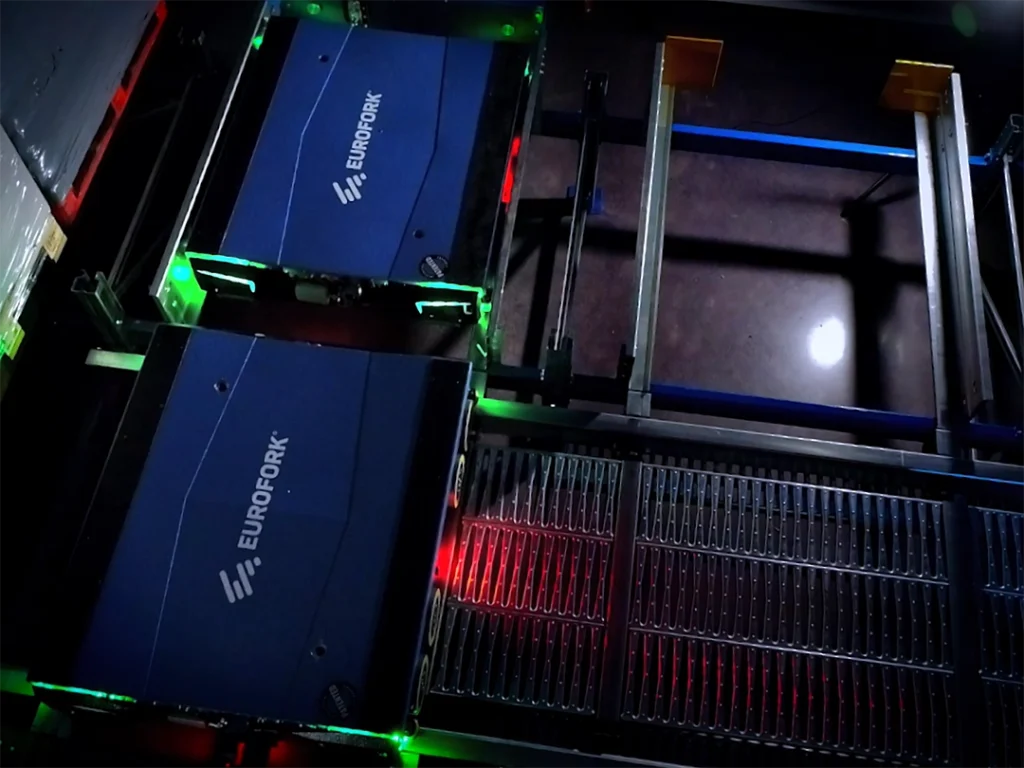

HIGH INTENSITY AND MINIMUM ERROR WITH E4CUBE®

The flexibility of E4CUBE® has enabled a major distribution center to increase the agility of operations in the crossdocking warehouse, allowing distributors to be more responsive to retailers and end users. One of our System Integrator partners successfully met the needs of their client, located in northeastern Italy, by delivering a standard Plug-and-Play warehouse ready in six months. This solution increased storage capacity by 25% thanks to the higher density of pallets that could be allocated within the warehouse.

Results

-75% REDUCTION IN ENERGY CONSUMPTION

MINIMIZATION OF SHIPMENT PREPARATION ERRORS

40% REDUCTION IN TCO (TOTAL COST OF OWNERSHIP)

25% INCREASE IN STORAGE CAPACITY

Requirements

The main request from our client was to completely transform the management of goods in a short period of time, converting a warehouse managed with VNA forklifts into a buffer to handle high runner Pallets as quickly as possible, both inbound and outbound. The challenge was to dedicate about 12% of the total 11,150 sqm area of the distribution center to a buffer for high runner items.

The primary objectives were four: maximizing storage capacity, reducing energy consumption, eliminating errors during the shipment preparation phase, and lowering the Total Cost of Ownership (TCO).

Sign up and

Read more

Enter your details to download the full case study